The fully automated Freezing tubes production line is a highly efficient, automated machine specifically developed for the production of medical and laboratory consumables. This line integrates aut

The fully automated Freezing tubes production line is a highly efficient, automated machine specifically developed for the production of medical and laboratory consumables.

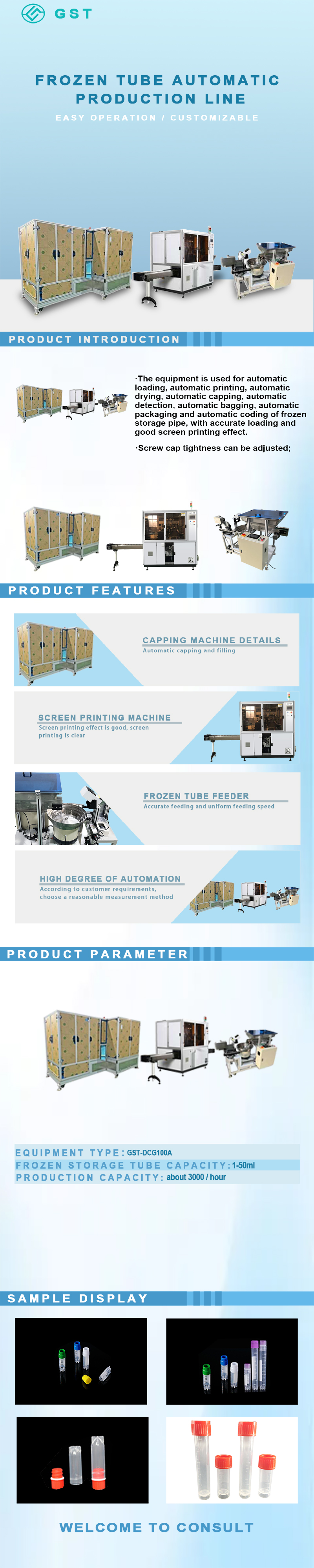

This line integrates automatic loading, precision screen printing, automatic capping, online inspection, intelligent counting, and packaging, comprehensively improving Freezing tubes production efficiency and quality.

The equipment's modular design allows for flexible customization and rapid switching between cryotubes of varying specifications to meet diverse production needs. Advanced visual inspection and leak detection systems ensure that each Freezing tubes is securely sealed and of consistent quality, meeting stringent medical and laboratory standards.

This fully automated Freezing tubes production line not only significantly reduces labor costs but also effectively minimizes human error, helping companies achieve scalable, intelligent, and standardized production goals. It is an ideal choice for medical device and consumables manufacturers to enhance their competitiveness.

Equipment features:

1) accurate loading of frozen storage tube automatic production line; 2) good silk screen printing effect; 3) adjustable tightness of capping; 4) adjustable packaging quantity.

Technical parameters:

Equipment Model: GST-DCG100A

Freezing tube capacity: 1-50ml

sizes: 3600*8 800*1800mm

production capacities: <2880 Pcs/hour 15ml: 50 Pcs/bag50ml: 25 Pcs/bag

power (output): 3KW

Customized Support: Yes