The centrifuge tube automatic production line is a fully automated production system tailored for the laboratory and medical consumables industries, covering multiple steps in the production process

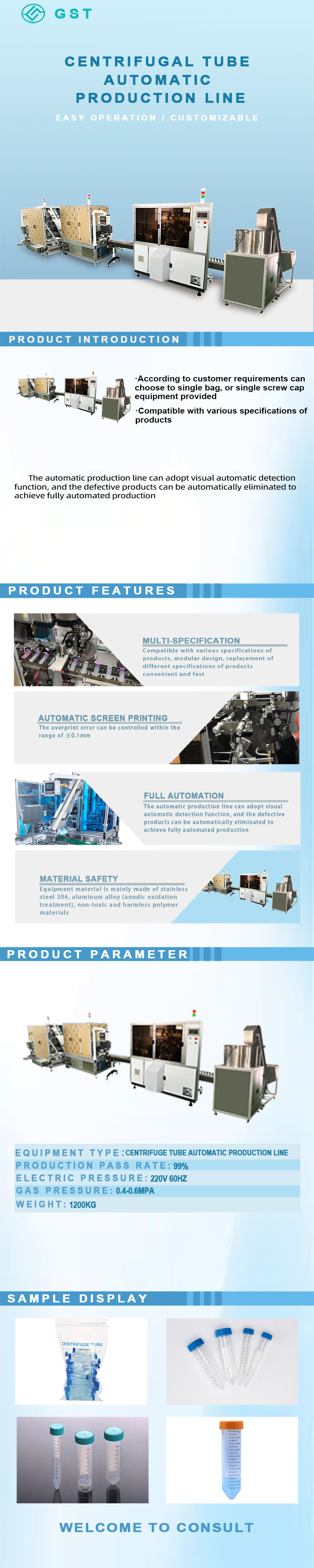

The centrifuge tube automatic production line is a fully automated production system tailored for the laboratory and medical consumables industries, covering multiple steps in the production process, from raw materials to finished product packaging. This line integrates functions such as automatic feeding, screen printing, capping, labeling, bagging, and coding, enabling standardized, high-speed, and continuous production of centrifuge tubes.

Precise feeding and automatic loading: The equipment utilizes a positioning feeding mechanism to accurately and orderly introduce centrifuge tubes into each stage of the production line.

High-quality printing and drying: The integrated screen printing module and drying unit enable high-quality printing of text, branding, and scales, along with rapid drying.

Adjustable capping and sealing: Adjustable capping torque ensures each tube is properly capped, balancing sealing performance with production speed.

In-line inspection and rejection: Each centrifuge tube is inspected during production, and defective products are automatically rejected to ensure the quality of the final product.

Flexible bagging and coding: Qualified tubes are automatically bagged/boxed, coded, and packaged, ensuring neat packaging and adjustable quantities.

Modular Design and Compatible Specifications: Different modules can be independently maintained, and parameters in each link can be flexibly adjusted to accommodate different tubing specifications.

Intelligent Control System: Utilizing PLC control and human-machine interface interaction, it supports status monitoring, fault alarms, and operational data logging.

This automated production line enables customers to significantly increase centrifuge tube production capacity, reduce manual labor, lower defective rates, and achieve large-scale, standardized production. Guanshentai's automated centrifuge tube production line, with its high level of integration, strong stability, and excellent compatibility, offers a strong competitive advantage in the medical device consumables manufacturing sector.

Technical parameters:

model number: GST-LXG100A

sizes: L8800*W1800*H1800mm

production capacities: 500pcs/min

power (output): 3KW

Customized Support: Yes