The automatic pipette leak detector is a high-precision quality inspection device designed specifically for pipette production lines. It automatically inspects pipettes for tightness, airtightness,

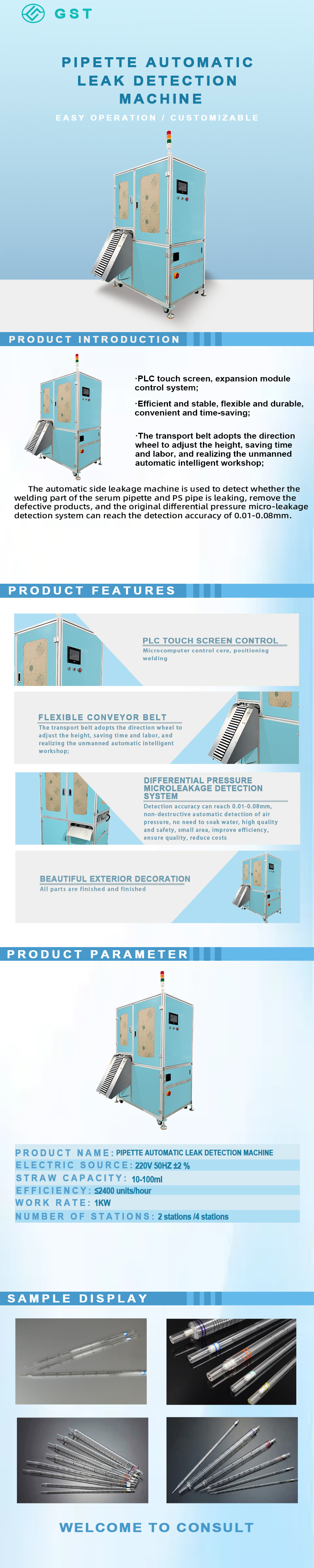

The automatic pipette leak detector is a high-precision quality inspection device designed specifically for pipette production lines. It automatically inspects pipettes for tightness, airtightness, or fluid-tightness after welding or sealing. This device can quickly identify leaks, seepage, or poorly sealed products during high-speed production, thereby improving product yield and reliability.

This device is typically integrated into automated pipette production lines, working alongside cutting, welding, screen printing, and assembly modules as part of the quality assurance process. Core Functions and Features:

High-precision gas/liquid leak detection: The device quickly verifies the leak tightness of each pipette through air pressure/vacuum testing, insertable differential pressure, or flow measurement.

Automatic loading and unloading integration: Seamlessly integrates with other production line modules to achieve automated feeding, testing, and rejection processes.

Modular design: The detection unit, control system, and air supply system are modularly arranged for easy maintenance, expansion, and upgrades.

Control and monitoring system: Equipped with a PLC control and human-machine interface (HMI), it supports setting detection parameters, real-time status monitoring, and automatic alarms.

Compatible with various sizes: Supports multiple pipette models (e.g., 1 ml, 5 ml, 10 ml, etc.). For inspections of pipettes (e.g., pipettes with a calibrated, non-contact, or non-contact pipette), simply replace the fixture or adjust the parameters.

High-speed inspection capability: It can process large batches of pipettes simultaneously, achieving high throughput inspection that matches the production line's pace.

Stability and reliability: Utilizing high-quality airtight components, valves, and sensors ensures long-term stable operation and low false positive rates.

By introducing an automatic pipette leak detector, manufacturers can immediately reject defective products after assembly, avoiding further processing and wasting resources. This improves overall product quality and reduces rework. It is an indispensable quality control device in modern pipette production lines.

Technical Parameters:

Model: GST-YYG104A

Pipette capacity: 10-100ml

sizes: 1700*1500*1850mm

production capacities: 2000-2400pcs/h

power (output): 1KW

Customized Support: Yes