The automatic ultrasonic pipette welding machine is an automated welding device designed specifically for the laboratory consumables industry. It is primarily used for high-strength, glue-free weldi

The automatic ultrasonic pipette welding machine is an automated welding device designed specifically for the laboratory consumables industry. It is primarily used for high-strength, glue-free welding of pipette tips or nozzles to pipette bodies. Integrating automatic loading, precise positioning, ultrasonic welding, and preliminary testing, the machine focuses on improving production efficiency, reducing labor costs, and ensuring weld consistency and reliability.

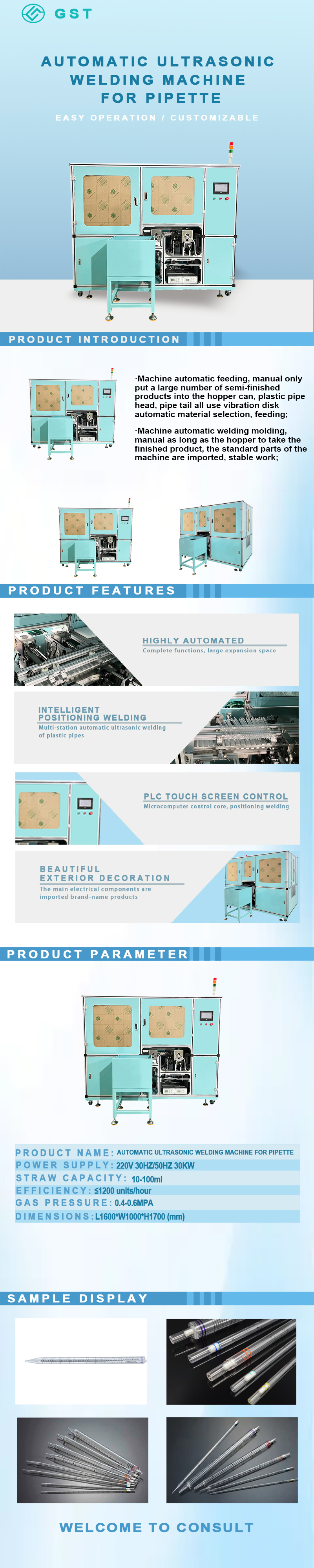

This automatic ultrasonic welding machine is suitable for automatically positioning and welding plastic tubing, PS tubing, pipettes, and other tubing. Its features include:

Automatic loading and feeding system: A vibrating plate automatically selects and feeds the pipe tips and tails, then transports the pipe bodies and sections to the welding station at the desired position.

Guan Shen Tai

Fully automatic welding and forming: After positioning, the ultrasonic welding head, driven by a control system, performs high-frequency vibrations at the interface to melt and fuse the plastic, achieving a glue-free connection.

High-quality components and precision manufacturing: The machine's standard parts are primarily imported brands, and all components feature a sophisticated surface finish, ensuring both aesthetics and reliability in both appearance and structure. In-line Air Tightness Testing (Optional): Select models can be integrated with an airtightness detection module to verify the seal of welded pipettes, improving product yield.

Furthermore, this equipment features a modular design, enabling easy line changeovers and adjustments to accommodate pipettes of varying capacities and sizes. The control system utilizes a PLC + human-machine interface (HMI) design, enabling intuitive parameter settings and operational status monitoring. It seamlessly integrates with upstream and downstream equipment (such as loading, testing, and cartoning equipment) to create an automated production line.

In short, the automatic ultrasonic pipette welding machine is a professional, efficient, and fully integrated welding solution. This equipment significantly improves the automation level, product consistency, and production stability of pipette production lines, making it a key option for labware manufacturers seeking intelligent upgrades.

Technical Parameters:

Equipment Model: GST-YYG103A

Pipette capacity: 10-100ml (1 set of equipment can only process a capacity of the pipette)

Ultrasonic equipment: Taiwan brand Evergreen 15-20K

sizes: L2500xW1500xH1200 (mm)

production capacities: 1100-1200 pcs/hour

power (output): 4.3KW

Customized Support: Yes