The automatic quantitative liquid filling machine is an intelligent device designed specifically for high-standard liquid packaging production. It is primarily used to precisely fill various liquids

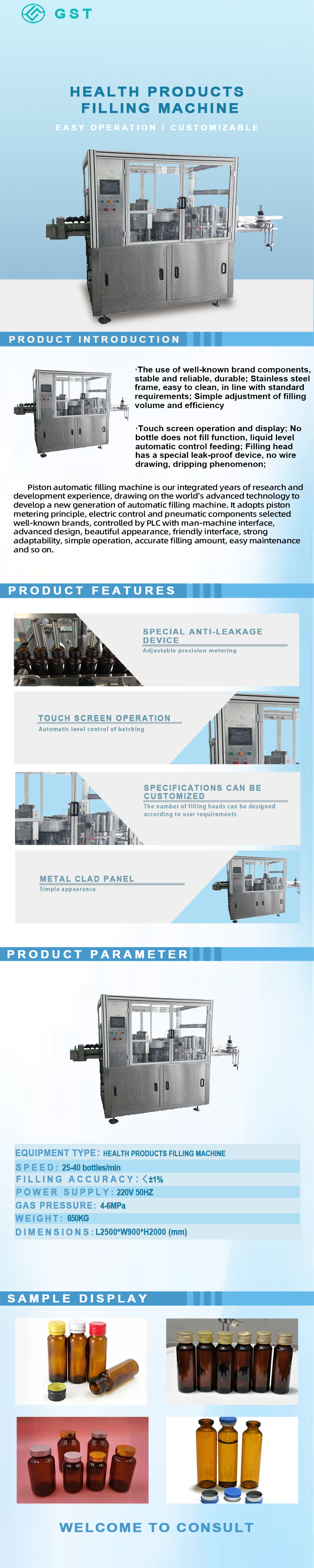

The automatic quantitative liquid filling machine is an intelligent device designed specifically for high-standard liquid packaging production. It is primarily used to precisely fill various liquids (including low-viscosity liquids, reagent solutions, medical solutions, cosmetics, and daily chemical lotions) into various containers (such as bottles, syringes, and reagent tubes) to preset volumes. Integrating a precision control system, an automatic feeding mechanism, and an anti-drip design, the machine achieves high accuracy, stability, and cleanliness without sacrificing speed.

High-precision metering control: Utilizing advanced servo drives or electronic flow control systems, the machine maintains minimal volumetric error for each fill, ensuring consistent filling and product quality.

Intelligent control interface: The machine is equipped with a PLC controller and a touchscreen interface, supporting parameter setting, batch saving and switching, and real-time monitoring of filling status, ensuring easy operation.

Anti-drip and bubble control: A fast-to-slow filling strategy, compensatory flow control, and a bubble removal mechanism minimize foaming and dripping.

Modular Structure and Easy-Clean Design: The modular design of all equipment components (filling heads, fluid circuits, and conveyor systems) allows for quick assembly and disassembly, cleaning, and compatibility with cleanroom environments.

Compatible with a variety of containers and liquids: By replacing the filling heads or adjusting parameters, the system can accommodate different container shapes, capacities, and viscosities.

Strong line integration capabilities: The system seamlessly integrates with upstream equipment such as feeding, capping, labeling, cleaning, testing, and packaging to create a complete automated liquid production line.

Technical parameters:

Model Number: GST-SWYP005A

Filling capacity: 25-250ml,50-500ml,150-1000ml,500-2500ml(different specifications can be ordered).

Canning efficiency: 25-40 bottles/minute (6 heads in the range of 50-500ml).

Canning precision: <±1%.

Power supply: 220V 50HZ.

Air pressure: 4-6MPa.

Overall dimension: 2500*900*2000mm.

Quality: 650KG.

Customized Support: Yes