The 96-well plate automatic filling, sealing, and labeling machine is a fully automated liquid handling device designed for high-throughput laboratories and the in vitro diagnostic (IVD) industry. T

The 96-well plate automatic filling, sealing, and labeling machine is a fully automated liquid handling device designed for high-throughput laboratories and the in vitro diagnostic (IVD) industry. This device performs the entire process of filling, sealing (or heat-sealing), and labeling 96-well plates in a single machine, significantly improving the efficiency and consistency of laboratory equipment production.

I. Core Functions and Process Flow

Automatic Plate Loading and Positioning: The device receives blank 96-well plates from a rack or conveyor system and uses a positioning mechanism to precisely align each well.

High-Precision Filling: A multi-channel filling head (such as a ceramic pump, peristaltic pump, or valve-controlled pump) delivers quantitative liquid to each well. Independently controlled, the filling volume and speed can be adjusted to accommodate varying liquid viscosities.

Sealing/Heat-Sealing Film Application: After filling, pre-cut or roll-type sealing film is automatically applied to the plate, sealed using heat and pressure.

Labeling: After sealing, the device automatically attaches labels (such as batch numbers, barcodes, or QR codes) to designated locations, facilitating downstream traceability and management.

Inline Inspection and Rejection: Equipped with visual recognition or photoelectric sensing systems, it inspects seal integrity, fill level, and label placement. Abnormal plates are automatically rejected or transferred to a rework channel.

II. Technical Features and Advantages

High Throughput and Efficiency: This integrated device can process large numbers of 96-well plates in a short period of time, making it suitable for large-scale reagent or biological sample production.

Precise Filling Control: Independent control of the multi-channel filling heads keeps errors within a low percentage range, enhancing the reliability of experimental results.

Flexible and Compatible Design: Supports various deep-well plate formats (such as standard 96-well plates, deep-well plates, and ELISA plates) by simply replacing fixtures or adjusting parameters.

Modular Structure: The filling, sealing, labeling, and inspection modules can be flexibly disassembled, operated, and maintained independently, improving equipment maintenance efficiency.

Cleanliness and Hygiene Guarantee: Components that come into contact with liquids or sensitive reagents are constructed from medical-grade stainless steel, corrosion-resistant materials, and sealed, making them suitable for cleanrooms or GMP-rated production facilities.

Strong Line Integration: Seamlessly integrates with upstream reagent preparation, sample loading/dilution systems, and downstream packaging and sealing equipment to create a complete automated production line.

This 96-well plate automatic filling, sealing, and labeling machine is ideal for processing PCR reagents, ELISA plates, deep-well plates, and diagnostic reagents. By integrating filling, sealing, and labeling, companies can save equipment space, reduce labor, and reduce intermediate transfers, while improving product yield and production efficiency.

Technical parameters:

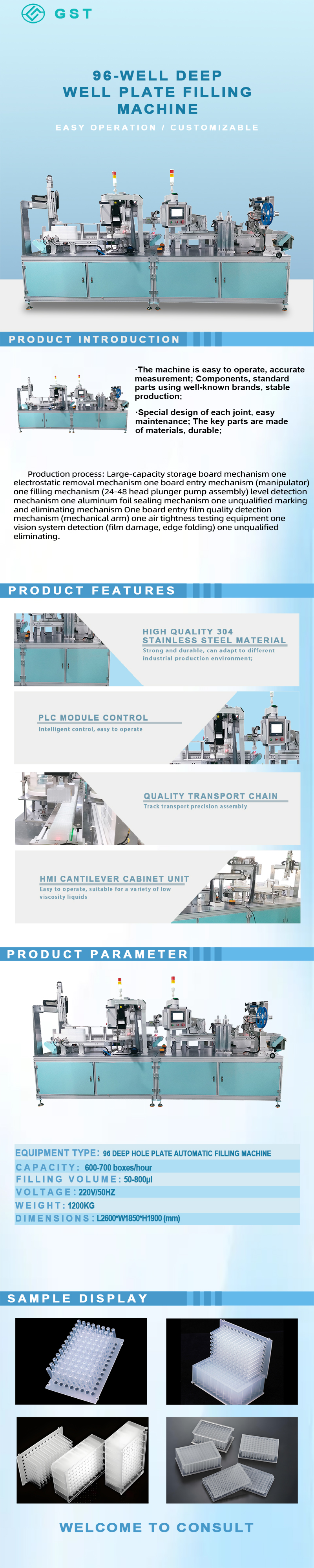

Model Number: GST-SWYP004A

96 head canning (plunger pump) (optional channel pipetting module) design capacity: 600-700 boxes / hour

Filling volume:50-800uL

Total power:5KW

Power supply voltage:220V/50HZ

Weight:1200KG

Overall dimension:L4200*W1200*H1800 (mm)

Customized Support: Yes