The automatic drug inspection machine is a high-precision, automated inspection device specifically developed for the pharmaceutical industry. It performs comprehensive optical inspections of pharma

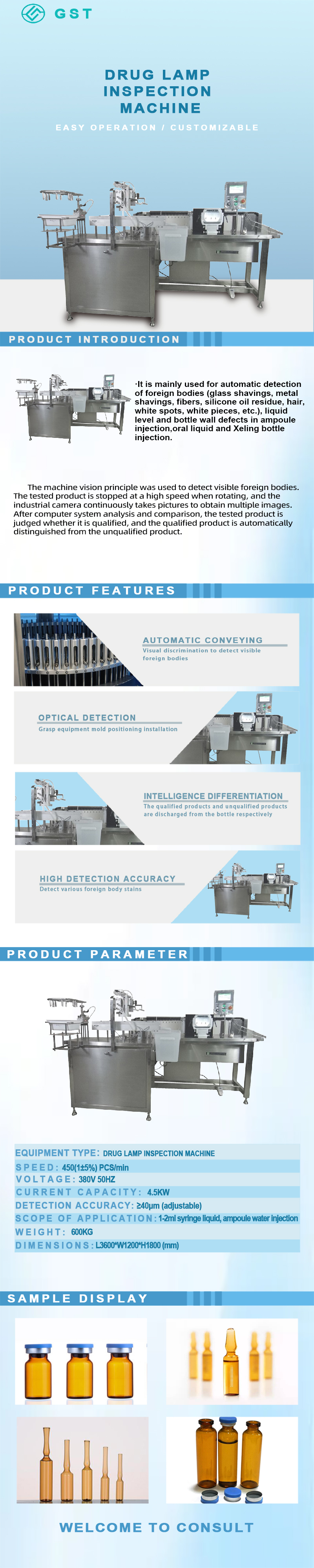

The automatic drug inspection machine is a high-precision, automated inspection device specifically developed for the pharmaceutical industry. It performs comprehensive optical inspections of pharmaceutical packaging containers, such as liquid bottles, ampoules, vials, and infusion bottles, for foreign matter, liquid levels, bubbles, cracks, particles, and label defects.

The machine integrates a high-speed visual recognition system, intelligent control algorithms, and a precise mechanical transmission structure to fully automatically inspect and reject pharmaceutical quality, ensuring that every bottle of liquid medicine is safe, qualified, and compliant with GMP production standards.

The machine utilizes a high-definition industrial camera and multi-angle LED cold light illumination technology, combined with proprietary image processing software, to capture and intelligently analyze high-resolution images of the bottle and its contents, effectively identifying tiny foreign matter, sediment, and surface defects.

Equipped with a high-speed servo drive and PLC intelligent control, the system implements a fully automated process from bottle loading, rotation, visual inspection, determination, to rejection. It can inspect hundreds of bottles per minute, meeting the needs of high-volume continuous production.

The automated pharmaceutical inspection machine features a modular design, allowing for flexible configuration of inspection stations for various bottle shapes and dosage forms. It seamlessly integrates with filling lines, labelers, cartoners, and other equipment to create a complete automated pharmaceutical inspection production line.

The system also features automatic statistics and data traceability, generating real-time inspection reports to facilitate quality analysis and production management.

Technical Parameters:

Model Number: GST-SWYP001A

Sizes: 3600*1200*1800mm

Applicable Scope: 1-2ml syringe liquid, ampoule injection;

Inspection Items: Visible foreign matter (glass shavings, metal shavings, silicone oil residue, fibers, white spots, white blocks), liquid level;

Inspection Speed: 450 (1±5%) pieces/minute;

Inspection Accuracy: ≥40 μm (adjustable);

Capacitance: 4.5 KW;

Voltage: AC380V, 50Hz;

Workbench Height: 900 mm;

Overall Dimensions: 3600 x 1200 x 1800 mm;

Weight: 600 kg

Customized Support: Yes