Semi-automatic liquid filling machines are high-precision, quantitative filling equipment designed specifically for liquid products (such as food and beverages, daily chemical liquids, pharmaceutica

Semi-automatic liquid filling machines are high-precision, quantitative filling equipment designed specifically for liquid products (such as food and beverages, daily chemical liquids, pharmaceutical liquids, and chemical solutions). Their primary goals are to improve filling efficiency, reduce labor costs, and ensure filling accuracy. They are suitable for small and medium-sized enterprises or high-variety, small-batch production environments.

Core Functions and Structure:

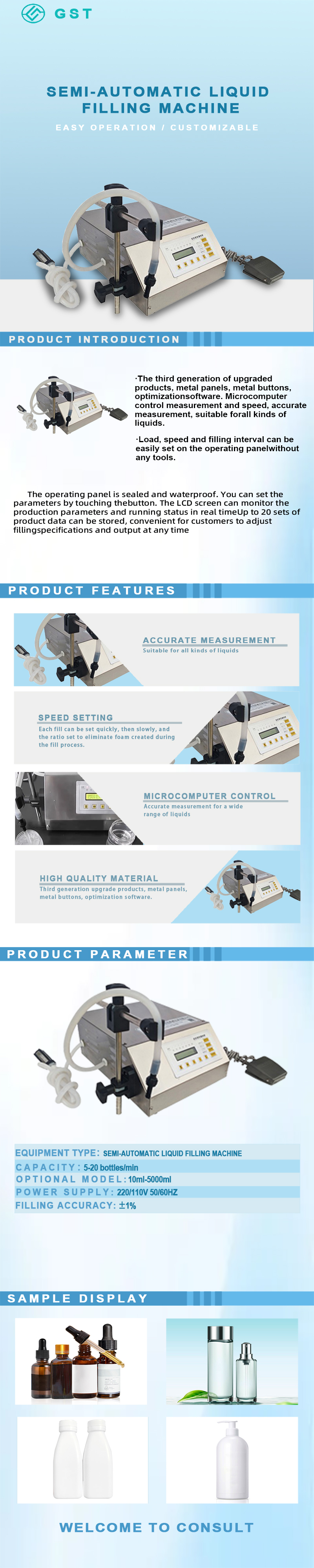

Precise Quantitative Filling: Guanshentai's semi-automatic liquid filling machines utilize a microcomputer control system, enabling precise control of filling volume, speed, and intervals. Each fill can be configured with a "fast first, slow later" mode to minimize foaming or bubbles.

Easy Operation: The machine features a metal panel, metal buttons, and an optimized software interface. Users can directly set the filling volume, speed, and interval on the panel, eliminating the need for complex tools and making adjustments faster. An LCD display provides real-time monitoring of production parameters and operating status.

High Hygienic Design: Liquid-contacting components are typically constructed of 304/316L stainless steel or food/pharmaceutical-grade materials, allowing for easy disassembly and cleaning, making it suitable for industries with high hygiene requirements.

Flexible Structure and Strong Scalability: The semi-automatic device is suitable for medium-volume production, high-volume product variations, and frequent specification changes. It can be used in conjunction with conveyor belts, with up to four units installed on one conveyor line.

Stable and Reliable: The device features a metal panel and sturdy construction, along with a dust- and waterproof control panel, ensuring long-term stable operation in industrial environments.

Applicable Industries and Applications

Food and Beverage: Sauces, beverages, liquid condiments, honey, etc.

Household Chemicals: Hand soap, shampoo, hair serum, liquid detergent, etc.

Pharmaceuticals: Oral liquids, medical solutions, reagent liquids, etc.

Chemicals: Lubricants, water-based solutions, cleaning agents, etc.

This device is particularly suitable for small and medium-sized manufacturers, or larger enterprises with multiple specifications and frequent production line changes.

Technical parameters:

Model Number: GST-SWYP002A

Sizes: 320*320*600mm

Production Capacities: 250pcs/h

Power (Output): 0.7KW

Customized Support: Yes