The hanger automatic pad printing and hot stamping machine is a highly efficient, automated device specifically designed for printing labels, logos, and decorative patterns on hangers. It integrates

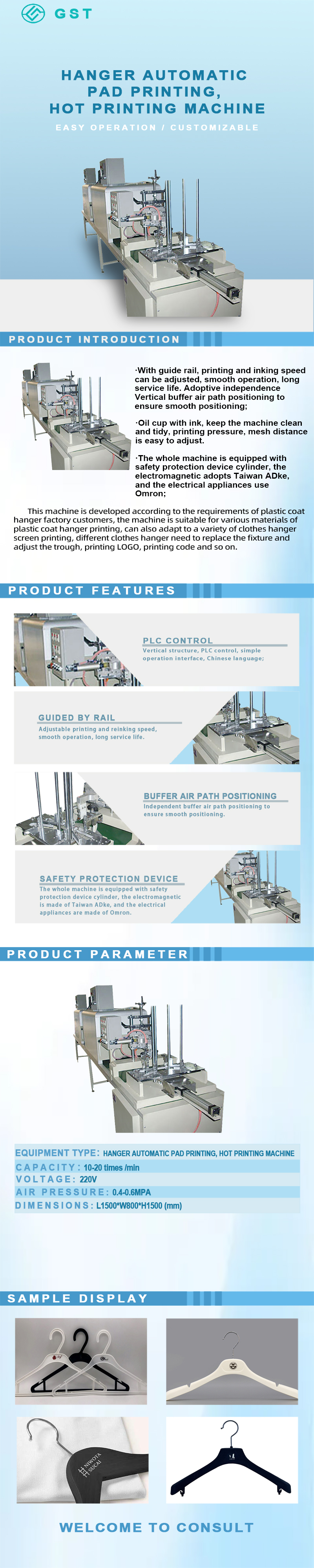

The hanger automatic pad printing and hot stamping machine is a highly efficient, automated device specifically designed for printing labels, logos, and decorative patterns on hangers. It integrates automatic loading, positioning, pad printing, hot stamping, and unloading, achieving high-precision printing and hot stamping effects on hangers made of various materials, including plastic, wood, and metal. This significantly improves production efficiency and print consistency, making it an ideal choice for modern hanger manufacturers seeking to upgrade to intelligent production.

I. Equipment Functions and Technical Features

Automatic Loading and Precise Positioning: Utilizing a servo-controlled conveying and positioning system, hangers automatically enter the workstation and are precisely positioned, effectively ensuring consistent printing position.

High-Precision Pad Printing System: Equipped with imported pad printing components and a flexible print head, the machine enables high-precision printing of multi-color patterns, logos, size numbers, and other designs, ensuring strong ink adhesion and sharp edges.

Integrated Hot Stamping Module: The hot stamping station supports gold and silver foil, as well as multi-color hot stamping films. Through constant temperature control and pressure regulation, the hot stamping station achieves vibrant colors, strong adhesion, and resistance to flaking.

Intelligent mold changeover design: The mold features a quick-change mechanism, adapting to different hanger models and shapes. Adjustment is convenient, meeting the needs of both high-variety, small-batch, and large-scale production.

Automatic unloading and inspection: Finished products are automatically unloaded, and an optional visual inspection system is available to automatically identify and reject print position deviations, missed prints, and poor hot stamping, ensuring product yield.

Intelligent control system: Utilizing PLC control and a touchscreen human-machine interface, the system offers flexible parameter settings and simple operation, along with fault alarms, statistical analysis, and recipe storage.

Equipment advantages: A high degree of automation reduces labor costs by over 70%. A single machine offers both pad printing and hot stamping, enhancing production flexibility. The system features clear, secure patterns, and high batch stability. Customization, custom development, and complete line integration are supported. The system can be integrated with a loader, drying line, and inspection system to create a fully automated printing production line.

Technical parameters:

Model Number: GST-WJ008A

Sizes: L1500*W800*H1500mm

Voltage: 220V AC

Air pressure: 0.4-0.6MPA.

Work efficiency: 10-20 times / min,

Cylinders, solenoid valves are made of Taiwan Yadek, and electrical appliances are made of Omron.

Customized Support: Yes