The trouser hanger automatic assembly machine is a smart, automated assembly device tailored specifically for the garment accessories industry. It is widely used in the efficient production of plast

The trouser hanger automatic assembly machine is a smart, automated assembly device tailored specifically for the garment accessories industry. It is widely used in the efficient production of plastic and metal trouser hangers, as well as multi-structure hangers.

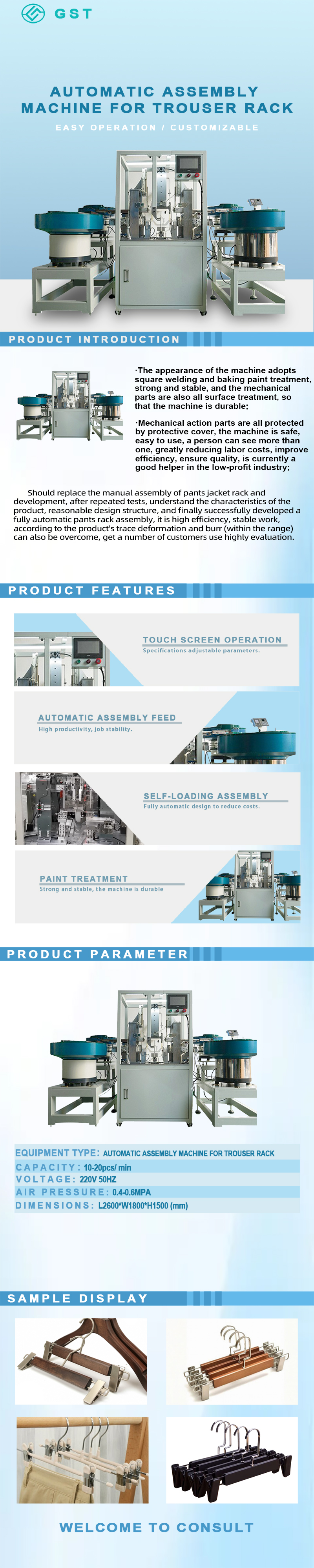

The machine utilizes a modular design concept. Through the perfect integration of a servo control system and high-precision mechanical structure, it automates the entire process, including automatic loading, precise positioning, assembly, inspection, and discharge of trouser hanger hooks, clips, and crossbars, significantly improving production efficiency and assembly consistency.

The machine is equipped with an intelligent visual inspection system that monitors component orientation and assembly quality in real time, automatically rejecting defective products and ensuring stable and reliable product delivery.

The system can quickly switch between workstations and parameters based on different trouser hanger specifications, supporting a variety of non-standard customization requirements and meeting customer flexible production requirements.

The PLC control system and touchscreen human-machine interface make operation simple and intuitive, and support data statistics, production monitoring, and remote maintenance.

This automatic assembly machine not only effectively reduces labor costs and defect rates, but also enables standardized and continuous production processes, making it an ideal choice for companies pursuing intelligent manufacturing and quality upgrades.

Technical parameters:

Model Number: GST-WJ009A

Voltage: 220V AC 50HZ

Air pressure: 0.4-0.6MPA

Working efficiency: 10-20/minute

Dimension: L2600*W1800*1500H

Customized Support: Yes