The automatic plastic wrap packaging machine is a highly efficient packaging machine designed specifically for food, fresh produce, daily chemicals, and light industrial products. It enables an inte

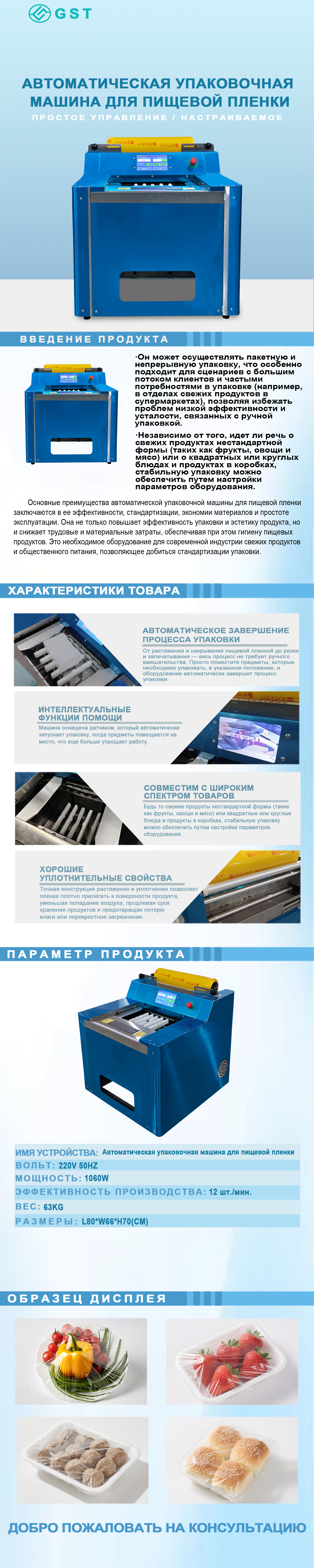

The automatic plastic wrap packaging machine is a highly efficient packaging machine designed specifically for food, fresh produce, daily chemicals, and light industrial products. It enables an integrated packaging process for automatic plastic wrap stretching, sealing, cutting, shaping, and discharging.

Core Functions and Technical Highlights

Automatic Film Stretching and Quantitative Wrapping: Equipped with a conveyor belt and film stretching system, the machine automatically stretches the plastic wrap to the set width and covers the product to be packaged, enabling rapid and continuous wrapping.

High-Precision Sealing and Cutting System: Utilizing a servo/pneumatically controlled hot knife or ultrasonic sealing unit, the packaging film is precisely cut and sealed, resulting in clean cuts and secure heat seals, effectively improving the appearance quality and sealing performance.

Intelligent Shaping and Discharging Module: After wrapping, the shaping mechanism ensures a smooth appearance of the package. The discharging and pushing system then transfers the finished product to the next process, supporting automatic stacking or transfer to the packaging line.

Modular Changeover Design: The machine supports rapid adjustment for different product sizes and film widths. Changeovers require only mold replacement or parameter adjustments, adapting to the production needs of multiple specifications, small batches, and a wide variety of products.

Clean Operation and Safety Protection: Suitable for packaging in the food and daily chemical industries, the machine features a dust-proof cover and dust-free operation. It is also equipped with a safety door, emergency stop button, and fault alarm system to ensure operator and equipment safety.

Intelligent Control and Data Management: The machine features a built-in PLC control system and touchscreen interface, supporting production data recording, parameter storage, fault notifications, and remote monitoring, enabling digital management of the packaging process.

Equipment Details:

Model Number: GST-WJ013A

Sizes: L80cm*W66cm*H70cm

Weight: 63kg

Power: 460W

Production Capacity: 12 pieces/minute

Voltage: 220V/50Hz

Core Component: Motor

Customized Support: Yes