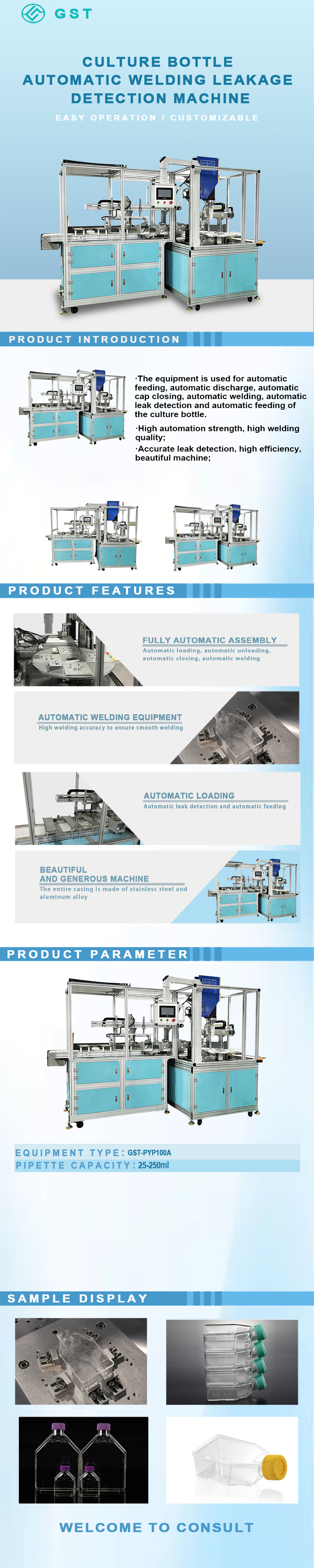

The Automatic Ultrasonic Welding and Leak Detection Machine for Culture Bottles is a highly efficient automated device integrating ultrasonic welding, seal detection, online rejection, and intellige

The Automatic Ultrasonic Welding and Leak Detection Machine for Culture Bottles is a highly efficient automated device integrating ultrasonic welding, seal detection, online rejection, and intelligent monitoring. It is specifically designed for manufacturers of biopharmaceuticals, laboratory consumables, and cell culture products.

The equipment uses high-frequency ultrasonic energy to quickly weld the bottle body and cap, resulting in strong, contamination-free welds. Subsequently, a precise airtightness detection module performs a full-scale leak test on each culture bottle, ensuring stable and reliable sealing performance and eliminating quality risks such as leakage and contamination at the source.

The entire machine employs an intelligent control system that seamlessly integrates with automated material handling, conveying, and packaging processes. It supports rapid switching between multiple culture bottle sizes and is suitable for large-scale, continuous production.

With its compact structure, small footprint, and easy operation, the machine also features data recording and anomaly alarm functions, helping companies achieve GMP-level production management.

Technical parameters:

Equipment Model: GST-PYP100A

Freezing tube capacity: 25-250ml

Sizes: L2550*W2000*H1500(mm)

Production Capacities: 600pcs/h

Power (Output): 1.5kw

Customized Support: Yes