The automated freezing tube production line is an intelligent and highly efficient production system designed for manufacturers of biological laboratory consumables. The equipment integrates multip

The automated freezing tube production line is an intelligent and highly efficient production system designed for manufacturers of biological laboratory consumables.

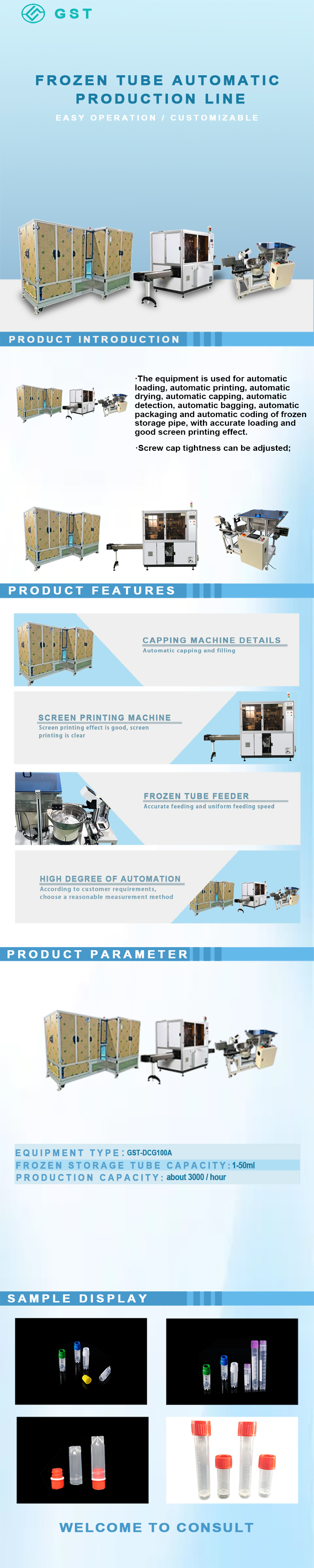

The equipment integrates multiple processes such as automatic feeding, capping and assembly, labeling and printing, visual inspection, counting, and packaging, enabling large-scale, continuous, and unmanned production of freezing tubes, significantly improving production line capacity and consistency.

The entire line adopts a modular design, allowing for flexible functional expansion according to enterprise needs. A high-speed servo drive system and CCD visual inspection module are installed at the core, enabling full inspection of freezing tube dimensions, burrs, foreign objects, and barcode quality, ensuring products meet medical-grade standards. Through an intelligent control system, production status, yield rate, and equipment alarms can be monitored in real time and managed remotely, comprehensively enhancing the factory's digitalization level.

This production line boasts advantages such as stable operation, convenient maintenance, and strong compatibility, adapting to various freezing tube sizes including 2ml, 5ml, and 10ml. It has significant value in improving the production efficiency of biological consumables, reducing labor costs, and realizing the construction of smart factories. Suitable for industries with high requirements for production capacity and quality, such as IVD consumables companies, biological laboratory consumables factories, and medical device manufacturers.

Technical parameters:

Equipment Model: GST-DCG100A

Freezing tube capacity: 1-50ml

Sizes: 3600*8 800*1800mm

Production Capacities: <2880 Pcs/hour 15ml: 50 Pcs/bag50ml: 25 Pcs/bag

Power (Output): 3KW

Customized Support: Yes