The 96-well deep plate automatic filling, sealing, and labeling machine is a fully automated, integrated workstation designed for modern molecular diagnostics, high-throughput screening, biological

The 96-well deep plate automatic filling, sealing, and labeling machine is a fully automated, integrated workstation designed for modern molecular diagnostics, high-throughput screening, biological sample banks, and other life science fields. It perfectly integrates three core processes: precise filling, sterile sealing, and automatic labeling, achieving fully automated operation of 96-well plates (compatible with 384-well plates) from liquid dispensing to final identification. It is an ideal choice for improving laboratory standardization and ensuring data traceability.

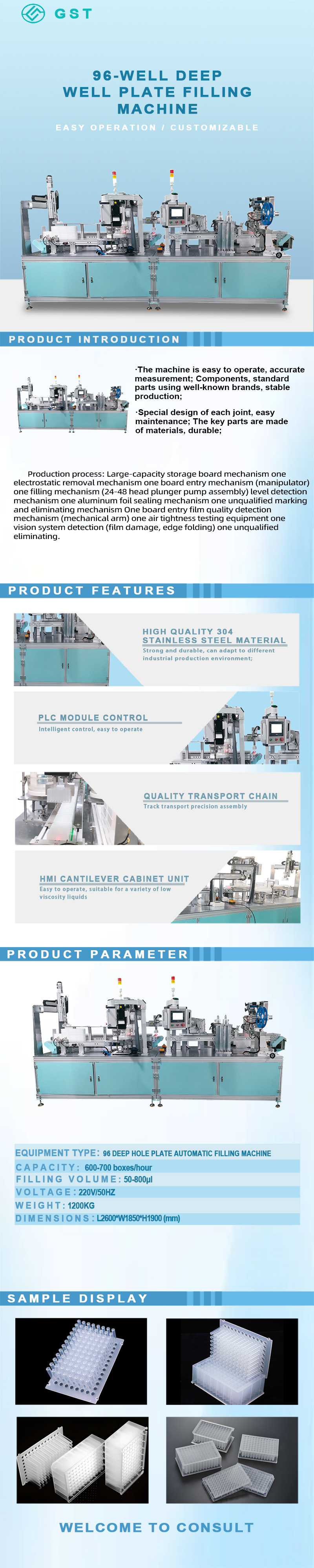

Core Functions and Advantages:

Efficient and Precise Filling: Utilizes high-precision syringe pumps or non-contact micro-dispensing technology, achieving single-well dispensing accuracy of ±0.5%, supporting liquid handling from µL to mL levels.

Supports complex procedures such as gradient dilution and multi-component addition, suitable for various applications including PCR system construction, cell drug addition, and reagent dispensing.

Reliable Sterile Sealing: Optional heat sealing or pressure-sensitive sealing methods provide airtight or pierceable seals, effectively preventing evaporation, contamination, and cross-contamination.

Precise and uniform temperature control ensures secure sealing without damaging the plate.

Intelligent Automatic Labeling and Identification: Integrates a high-resolution vision system for automatic reading, printing, and precise application of one-dimensional/two-dimensional barcodes, or direct laser marking of the plates.

Ensures each plate has a unique identifier, seamlessly integrating with LIMS systems for full sample lifecycle traceability.

Modular and Flexible Design: Customizable module combinations based on user workflows, with flexible upgrade and expansion capabilities.

Excellent Anti-Contamination Design: Utilizes laminar flow positive pressure or built-in HEPA filtration systems, achieving ISO 5 cleanroom standards in critical areas, meeting the requirements of highly sensitive experiments.

Intuitive and Intelligent Software: Equipped with a user-friendly graphical interface, supporting free protocol editing, parameter storage and retrieval, and complete electronic record and audit trail functions.

Excellent Stability and Throughput: Supports continuous automatic processing of hundreds of plates, stable 7x24 operation, significantly reducing labor and improving experimental reproducibility and throughput.

Equipment Details:

Model Number: GST-SWYP004A

Sizes: L4200*W1200*H1800 (mm)

Production Capacities: 600-700 boxes/hour

Filling volume:50-800uL

Total power:5KW

Power supply voltage:220V/50HZ

Weight:1200KG

Customized Support: Yes