The semi-automatic paste filling machine is an ideal device designed for small to medium-scale production, multi-product changeovers, and high-precision filling requirements. It cleverly combines th

The semi-automatic paste filling machine is an ideal device designed for small to medium-scale production, multi-product changeovers, and high-precision filling requirements. It cleverly combines the precision of automated metering with the flexibility of manual operation, providing an economical and reliable professional filling solution for viscous materials such as creams, emulsions, and sauces in the cosmetics, pharmaceutical, food, and chemical industries.

Key Advantages:

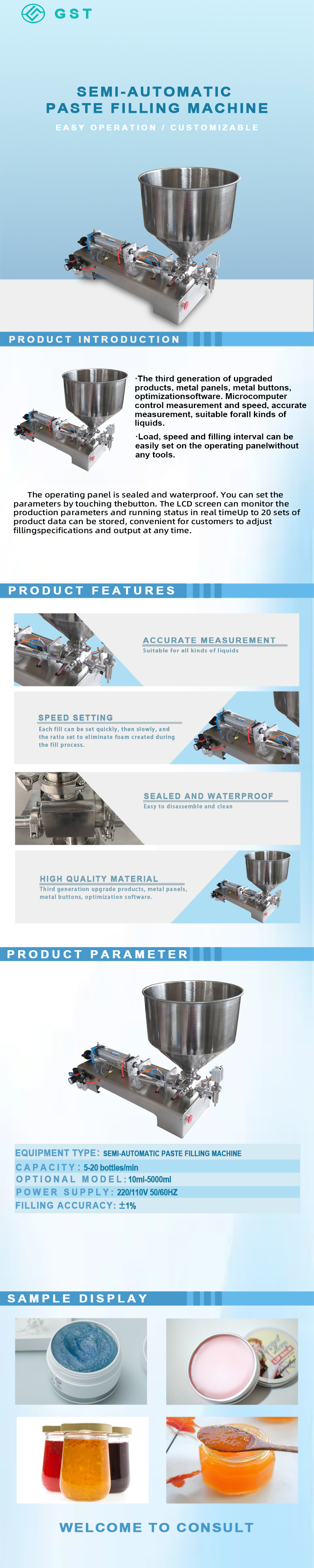

High-precision filling: Utilizing a precision piston pump or peristaltic pump for metering, combined with a fine-tuning control system, it achieves high filling accuracy and excellent repeatability, effectively reducing material waste.

Wide material adaptability: Specifically designed for viscous fluids, it can easily handle filling from light lotions to high-viscosity pastes, without foaming or dripping.

Simple and flexible operation: Human-machine collaborative mode, with foot switch or manual trigger filling. Product changeovers only require simple replacement of the filling nozzle and parameter adjustment, without complex debugging.

Robust and hygienic design: Main contact parts are made of high-quality stainless steel, meeting food and pharmaceutical production hygiene requirements, and are easy to disassemble and clean.

High cost-effectiveness: With a moderate investment, it significantly improves filling accuracy and efficiency, making it an excellent choice for small-scale production, prototyping, and multi-product changeover production.

Technical parameters:

Model Number: GST-SWYP003A

Sizes: 1600*300*1000mm

Optional models: 10ml -5000ml ;

Power supply: 220/110V 50/60HZ.

Air pressure: 0.4-0.6MPa.

Filling speed: 5-20 bottles/minute (the machine power for the gas source, can meet the large and small enterprises to use);.

Filling precision: ≤±1%.

Customized Support: Yes