The oral mirror automatic assembly machine is specifically designed for the fully automatic, sterile assembly of disposable medical oral mirrors. The equipment integrates lens positioning, handle pr

The oral mirror automatic assembly machine is specifically designed for the fully automatic, sterile assembly of disposable medical oral mirrors. The equipment integrates lens positioning, handle pressing, protective film application, and functional testing, achieving high-precision, high-efficiency automated assembly under controlled cleanroom conditions. It fully meets the GMP regulations for medical devices and sterile production requirements.

Cleanroom Precision Assembly: Equipped with a Class 100 cleanroom module and positive pressure dust prevention system, key workstations achieve ISO 5 cleanliness levels, ensuring dust-free operation during lens and handle assembly.

Sub-millimeter Positioning and Pressing: Utilizing visual guidance and servo pressure control, the lens positioning accuracy is ±0.05mm, with dynamic adjustment of pressing force, resulting in a handle assembly pass rate of ≥99.9%.

Multi-functional Integrated Testing: Simultaneously performs mirror surface defect detection, angle deviation measurement, and protective film application integrity verification, with automatic rejection of defective products.

High-Speed Flexible Production: Modular design adapts to various specifications (adult/child, regular/anti-fog models), with a single machine capacity of up to 150 units per minute, and supports intelligent connection with upstream injection molding and downstream packaging equipment.

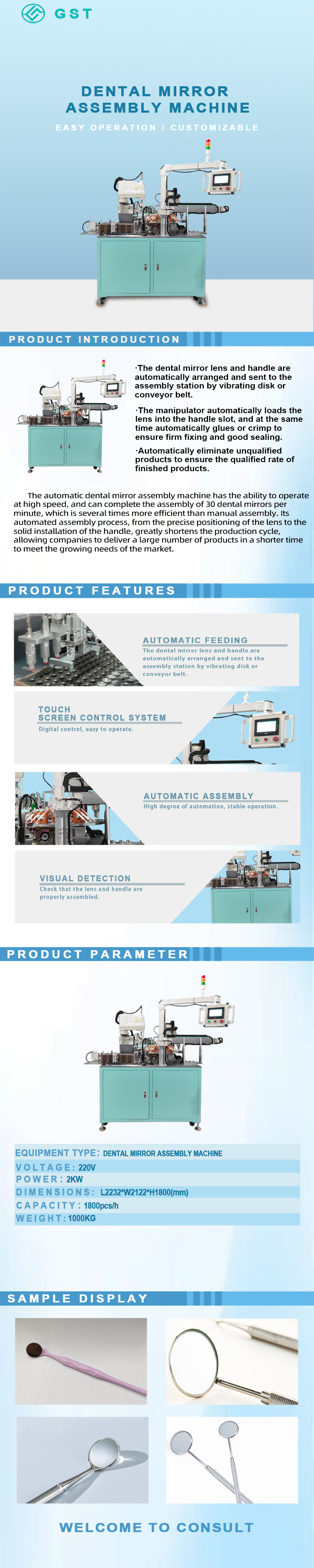

Technical parameters:

Model Number: GST-BC004

Sizes: L2232*W2122*H1800(mm)

Production Capacities: 150-200pcs/min

Power (Output): 3KW,220V

Weight:1000KG

Customized Support: Yes