Release Date:2024-02-23 11:41:58 Popularity:

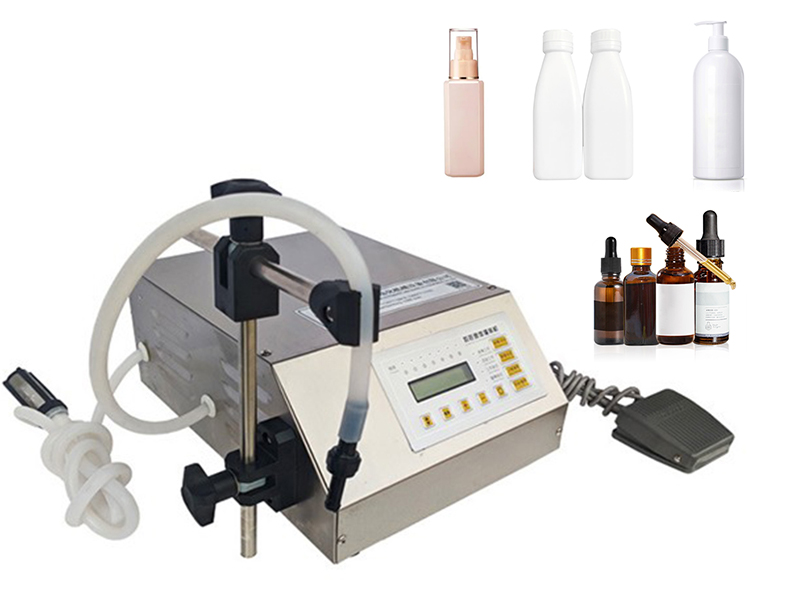

In modern production lines, small automatic filling machines have gradually become the equipment of choice for many companies due to their high efficiency, accuracy and labor saving characteristics. However, in the face of a dazzling array of products on the market, how to choose a cost-effective and suitable small automatic filling machine has become the focus of many companies. This article will analyze the price of small automatic filling machines to help readers better understand the market and make informed purchasing decisions.

1. Analysis of price factors of small automatic filling machines

The price of small automatic filling machines is affected by many factors, including brand, function, material, technical level, etc. Generally speaking, products from well-known brands tend to be more expensive, but their quality and after-sales service are also more guaranteed; equipment with rich functions can meet more production needs, but the price will also increase accordingly; high-quality materials and technical levels can ensure that the equipment The durability and stability will also have an impact on the price.

2. How to choose a suitable small automatic filling machine

Clarify production needs: When choosing a small automatic filling machine, you must first clarify your production needs, including the type of filling materials, output requirements, accuracy requirements, etc. This helps to select equipment that meets your production needs and avoids failure to meet production requirements after purchase.

Compare market prices: After understanding your own production needs, you can obtain price information on small automatic filling machines of different brands and models on the market through online searches, exhibitions, and manufacturer consultations. At the same time, pay attention to comparing the cost performance of different products, and do not blindly pursue low or high prices.

Pay attention to product quality and after-sales service: When purchasing a small automatic filling machine, in addition to price factors, you must also pay attention to product quality and after-sales service. High-quality products can ensure the stable operation of the production line and reduce the failure rate; perfect after-sales service can provide timely technical support and maintenance services when equipment problems arise.

3. Market development trend of small automatic filling machines

With the continuous advancement of science and technology and the intensification of market competition, the small automatic filling machine market has shown the following development trends:

Technological innovation: With the continuous development of intelligent and automation technology, small automatic filling machines will pay more attention to technological innovation and improve the automation and intelligence level of the equipment.

Personalized customization: With the diversification of market demand, small automatic filling machines will pay more attention to personalized customization to meet the production needs of different companies.

Environmental protection and energy saving: Today, with the increasing awareness of environmental protection, small automatic filling machines will pay more attention to environmental protection and energy saving design to reduce energy consumption and environmental pollution.

In short, choosing a small automatic filling machine that is cost-effective and suitable for you is of great significance to the company's production efficiency and cost control. During the purchasing process, factors such as production needs, price factors, product quality, and after-sales service must be fully considered to make wise decisions. At the same time, we must also pay attention to market development trends in order to promptly adjust production equipment and strategies to maintain the competitiveness of the enterprise.