Release Date:2024-09-12 14:50:48 Popularity:

With the advent of the Industry 4.0 era, the global manufacturing industry is experiencing a profound change, and automated assembly lines, as one of the core technologies, are redefining the traditional production model. This type of production line realizes the whole process of automation from parts assembly to finished product packaging by integrating automation equipment, intelligent control system and data analysis technology. This not only greatly improves the production efficiency, but also brings higher product quality and lower production cost for enterprises. In this paper, we will discuss the working principle and advantages of automated assembly production line and its far-reaching impact on the manufacturing industry.

First, the definition and working principle of automated assembly line

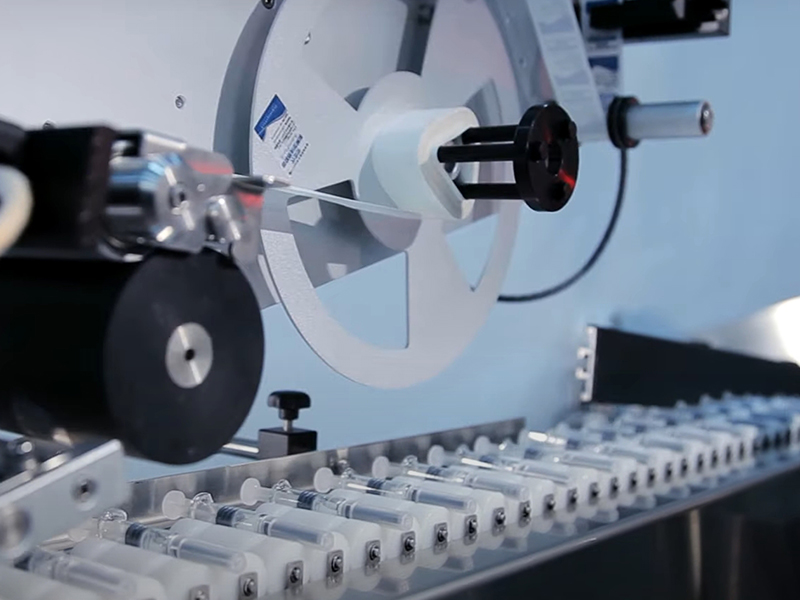

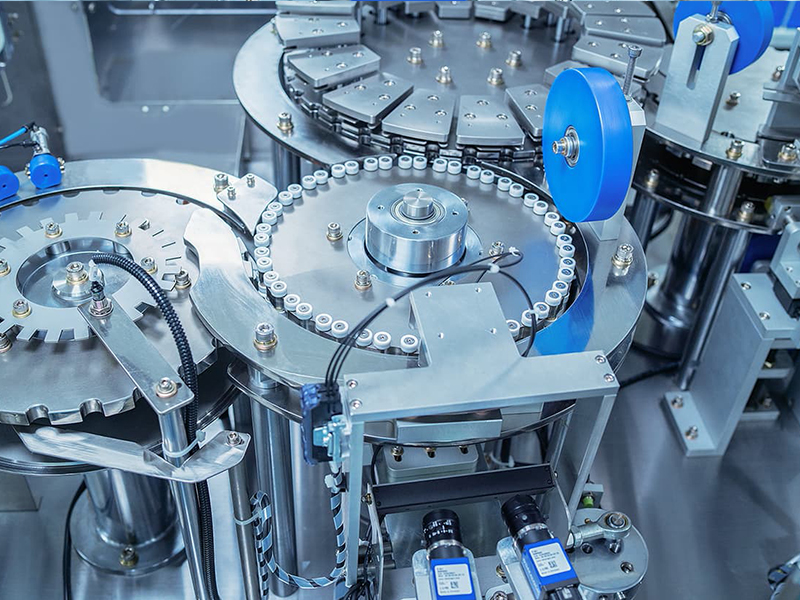

Automated assembly line is a variety of automation equipment and systems integrated into a production line, can be completed in the case of unmanned intervention in the product assembly, testing and packaging and other processes of the production model. This kind of production line usually consists of manipulators, sensors, PLC control systems, conveyor systems and monitoring systems. Each link is controlled by computers or other intelligent devices to realize efficient automated production.

The working principle can be summarized as follows:

1. Parts feeding: parts are accurately transferred to each station of the production line through the automated feeding system.

2. Assembly and processing: Various types of manipulators, welding equipment or other assembly tools are coordinated by the control system to assemble or process the parts.

3. Quality Inspection: The production line is equipped with sensors and inspection equipment, which can monitor each production link in real time to ensure that the products meet the quality standards.

4. Finished product output and packaging: after the assembly is completed, the products are transported to the packaging system to realize fully automated packaging.

Second, the advantages of automated assembly line

1. Improve production efficiency: automated assembly line can realize continuous operation, which greatly improves the production efficiency. Compared with the traditional manual operation, the automated production line can complete the production of larger quantities of products in a shorter period of time, and at the same time reduce the waste of time brought about by manual operation.

2. Reduce production costs: Although the automated assembly line is a large investment in the early stage, but its long-term operation can significantly reduce production costs. The stability and efficiency of automated equipment reduces the need for labor and reduces material waste and rework costs due to human error.

3. Improve product quality and consistency: automated equipment in the production of a high degree of consistency in the operation of precision, to ensure that the quality of each product meets the standard. Traditional manual operation is difficult to achieve this consistency, while automated equipment can be programmed to control and ensure stable product quality.

4. Enhance the flexibility of the production line: modern automated assembly line has a high degree of flexibility, can quickly adapt to different specifications or types of products by modifying the control program. This flexibility makes the enterprise in the face of diversified market demand, can adjust the production line in time to meet the individual needs of customers.

5. Improve production safety: automated production lines can reduce the opportunity for workers to come into contact with dangerous machinery or hazardous environments, significantly improving the safety of the production process. Workers are only responsible for the maintenance and supervision of equipment, reducing the possibility of accidents in high-risk operations.

Third, the application areas of automated assembly line

Automated assembly line has been widely used in many industries, including automotive, electronics, medical equipment, home appliances, toys and other fields.

1. Automobile industry: automobile manufacturing requires highly complex assembly process, automated production line can realize efficient assembly of engine, transmission and other key components, and can carry out real-time quality monitoring through sensor technology.

2. Electronic product manufacturing: electronic products are usually characterized by miniaturization and precision, automated assembly line can complete the precise assembly of circuit boards, chips and other micro-parts through high-precision robotic arms to ensure high quality products.

3. Medical equipment production: medical equipment requires high cleanliness and high precision, automated production line can ensure that the production process is pollution-free, and through precise assembly operations to improve the product qualification rate.

4. Household appliances and toys manufacturing: household appliances and toys assembly workload, repetitive, automated assembly line can efficiently handle these high-volume, low-complexity products, reduce labor costs and improve production efficiency.

Fourth, the future trend of automated assembly line

1. Intelligent and autonomous: with the development of artificial intelligence and big data technology, the future automated assembly line will be more intelligent. Through data analysis and machine learning, the production line can autonomously adjust the operation process, optimize production efficiency and product quality.

2. Flexible manufacturing: the future automated production line will be more flexible, able to quickly adjust the production process to cope with different specifications and batch product demand. This flexible manufacturing model will provide companies with greater market resilience.

3. Green production and sustainable development: with the increasingly stringent environmental regulations, the automated assembly line will pay more attention to the application of energy-saving and environmentally friendly technologies to achieve sustainable production by reducing energy consumption and waste emissions.

As one of the core technologies of Industry 4.0, automated assembly line is continuously promoting the manufacturing industry to develop in the direction of high efficiency, intelligence and green. It not only provides enterprises with an effective way to improve production efficiency and product quality, but also reduces production costs and labor intensity. In the future, with the further development of science and technology, automated assembly line will show its great potential in more fields and become an indispensable and important part of the global manufacturing industry.