Release Date:2025-07-09 15:14:36 Popularity:

In the fields of precision experiments such as medical treatment, scientific research, and biopharmaceuticals, centrifuge tubes are widely used in sample collection, storage, and centrifugal separation as one of the basic experimental consumables. In the mass production of centrifuge tubes, traditional manual printing or monochrome mechanical printing has been difficult to meet the requirements of efficiency, accuracy, and consistency. The application of automatic screen printers for centrifuge tubes has brought efficient, high-quality, and standardized solutions to production companies, helping them maintain their competitive advantage in the market.

1. The importance of screen printing in centrifuge tube production

Screen printing of centrifuge tubes is not only a beautiful decoration, but also a core part of functionality. Common printing content includes:

Capacity scale: convenient for accurate sample measurement;

Batch number and date: used for quality tracking and supervision;

Brand logo or customized pattern: improve brand recognition;

Symbols and instructions: such as "sterilization" and "sterile" certification marks.

In the experimental environment, extremely high requirements are placed on the clarity, wear resistance, and adhesion of the scale. Therefore, the traditional thermal transfer, pad printing or manual printing methods are gradually being replaced by automatic screen printing technology due to defects such as low efficiency, easy deviation, and poor scrubbing resistance.

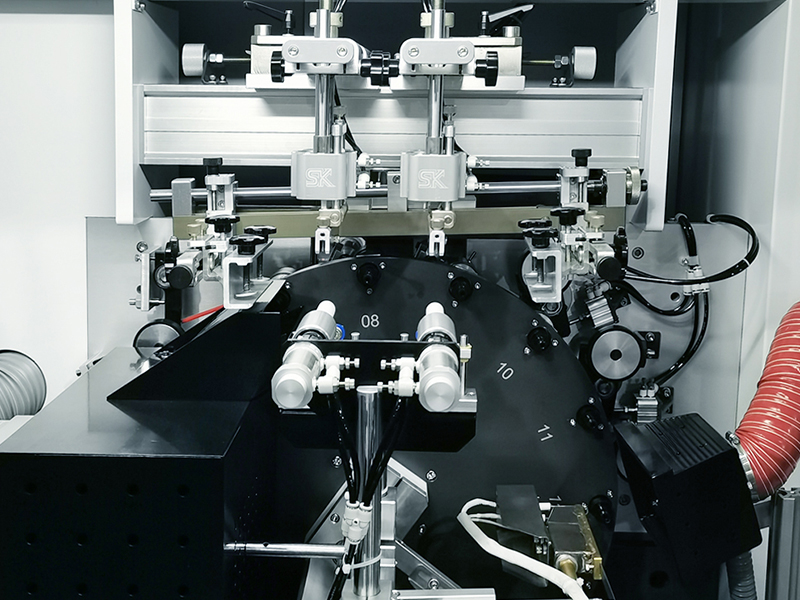

2. Structural composition and working principle of centrifuge tube automatic screen printer

Automatic screen printer is a device that combines screen printing technology with an automated control system, and is specifically used for high-precision printing on the surface of tubular and cylindrical plastic products. Its main components include:

Automatic feeding system: Use a vibrating plate or conveyor belt to automatically arrange and transport the centrifuge tubes to be printed to the screen printing station to reduce manual intervention.

Positioning fixture system: Precisely clamp and rotate the centrifuge tube to keep it synchronized with the printing head to ensure that the printed pattern is in the specified position.

Screen printing system: Use a high-precision screen template and ink scraping system to evenly print the ink on the surface of the tube during rolling.

Ink drying device: Equipped with UV curing lamp or hot air drying system to quickly cure the ink and improve adhesion and production efficiency.

Visual inspection and rejection system (optional): Check whether the printing is complete and the alignment is accurate through the CCD image recognition system, and automatically reject unqualified products.

Intelligent control system (HMI): Operators can set parameters such as printing speed, pattern position, color switching, etc. through the touch screen, which is convenient and efficient.

3. Analysis of technical advantages

High speed and high efficiency, improving production capacity: an automatic screen printer can achieve efficient printing of 60 to 120 centrifuge tubes per minute, which is much higher than manual and semi-automatic equipment.

High printing accuracy and accurate alignment: with servo motors and precision fixtures, the pattern deviation control within ±0.1mm is achieved, and the scale lines are neat and clear.

Multi-color printing capability: single-color, two-color or even multi-color printing systems can be configured to achieve color separation of brand logos and scale lines, which is beautiful and generous.

Strong ink adhesion and friction resistance: medical-grade environmentally friendly inks are selected, combined with UV curing technology to ensure that the printed pattern is scrub-resistant, non-fading, and resistant to alcohol disinfection.

Strong compatibility and fast changeover: It can adapt to centrifuge tubes of different specifications such as 1.5mL, 15mL, and 50mL, with short changeover time and improved flexible manufacturing capabilities.

Whole-line integration and high degree of automation: It can be linked with automatic feeders, welding machines, capping machines, and cartoning machines to form a complete production line to improve the level of automation.

Driven by the wave of automation and digital manufacturing, centrifuge tube automatic screen printers have become important equipment for experimental consumables companies to improve production capacity and brand image. It not only performs well in efficiency, precision, and stability, but also helps companies establish a unified quality standard system and enhance market competitiveness.