Release Date:2025-07-09 14:02:00 Popularity:

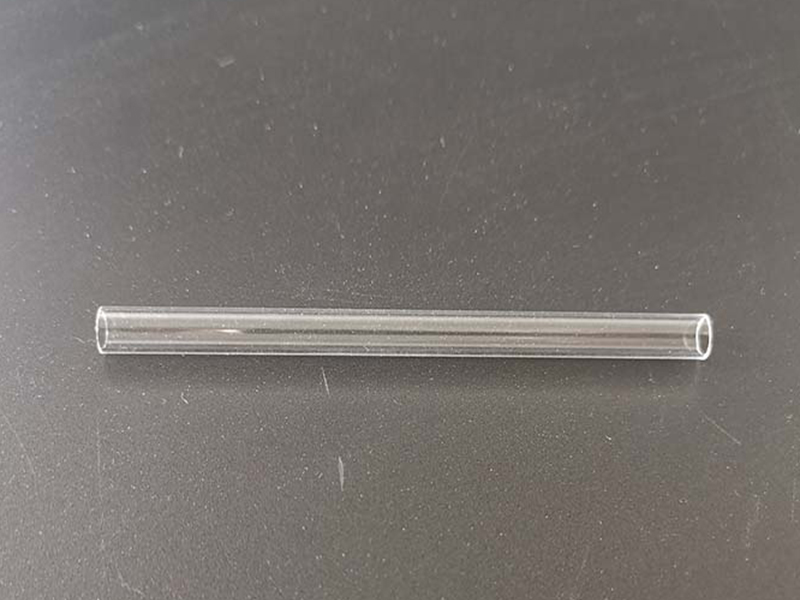

The automatic chip blower for pipettes is one of the important equipment to ensure the clean quality of pipettes and the efficiency of automated production lines. In the production process of pipettes, processing links such as automatic tube cutting machines, ultrasonic welding machines, and screen printing machines will produce plastic chips, electrostatically attached dust or fine residues to varying degrees. These impurities often remain in the inner cavity or outer wall of the pipette. Especially for experimental environments with micron-level operations, even a very small amount of residue will pose a pollution hazard.

Traditional cleaning methods such as manual scrubbing, vacuuming or alcohol wiping are not only inefficient, but also difficult to completely remove fine particles, and are very easy to introduce new sources of pollution, which cannot meet the requirements of large-scale production and medical-grade dust-free standards. Therefore, an efficient, non-contact, and non-damaging automated cleaning method is particularly important.

1. Structural principle of the automatic chip blower for pipettes

The automatic chip blower for pipettes is an automated equipment designed for the cleaning process in the pipette manufacturing process. It mainly removes debris, dust and electrostatic attachments inside and outside the pipette by blowing away compressed air. Its basic structure and working principle are as follows:

Automatic feeding system: Use conveyor belt, turntable or manipulator to orderly send the pipettes to be blown into the cleaning channel.

Multi-channel blowing mechanism: Equipped with multiple adjustable angle air nozzles, strong air flow is simultaneously performed on the inner cavity, nozzle and outer wall of the tube body. The air pressure can be set according to the product material, generally controlled between 0.3 and 0.6Mpa.

High-efficiency electrostatic dust removal system (optional): Add an electrostatic rod or ion air nozzle device to effectively neutralize the static electricity on the plastic surface and prevent fine dust from adhering and rebounding.

Negative pressure chip removal device: With a dust collector or industrial dust collection system, the blown debris will be recovered in time to avoid secondary pollution.

Intelligent control system: The touch screen sets parameters such as blowing time, air pressure, switching product models, etc., automatically counts and can be integrated into the MES system.

Automatic unloading and docking production line: The pipettes that have been blown are automatically classified and unloaded, and can be seamlessly connected to subsequent processes such as stretching, plugging, and packaging to achieve integrated linkage.

2. Analysis of Equipment Advantages

High efficiency and cleanliness, eliminating impurity pollution: high pressure airflow + multi-angle blowing, effectively removing dust and chips, the inner wall cleanliness can reach medical grade standards, in line with GMP production specifications.

Non-contact operation, zero risk of damage: the entire cleaning process does not touch the surface of the tube body, avoiding physical scratches or scratches, ensuring the integrity of the product appearance.

Stable and reliable, adaptable to a variety of specifications: adapt to various sizes of pipettes such as 1mL, 5mL, 10mL, 25mL, etc., quickly switch molds or set parameters.

Save manpower and increase production capacity: replace cumbersome manual cleaning, a single machine processes hundreds of products per minute, effectively shortening the production line cycle time.

Energy saving and environmental protection, automatic recycling of debris: the supporting dust removal system centrally processes the debris, improves the air quality of the workshop, and meets modern environmental protection requirements.

Flexible integration, support production line linkage: can be used independently, or embedded in production lines such as stretching, welding, and printing to form a closed-loop cleaning system.

Today, as the pursuit of "zero pollution" and "high cleanliness" for laboratory consumables in the medical and scientific research fields becomes increasingly stringent, the automatic chip blower for pipettes is gradually becoming a key link for pipette manufacturers to improve product quality, increase production efficiency and build intelligent factories. It not only fills the cleaning gap in the high-end manufacturing process, but also injects strong impetus into the laboratory consumables industry towards standardization, automation and cleanliness.