Release Date:2025-07-16 11:54:58 Popularity:

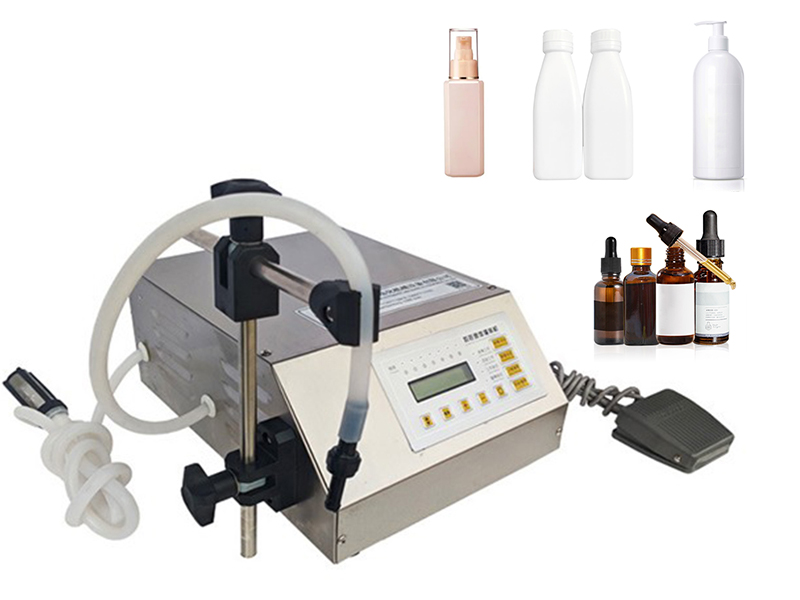

The automatic perfume filling machine is an automated filling equipment specially designed for low-viscosity, high-volatility liquid products such as perfume. It can automatically complete multiple processes such as quantitative filling, capping, nozzle tightening and packaging output of perfume bottles under the conditions of no pollution, constant temperature and precise control. This equipment is not only suitable for standard bottle types, but also supports glass bottles or plastic bottles of various specifications and materials. It is a core component of modern perfume production lines.

1. Main structure and functional modules

Automatic bottle sorting system: Automatically arrange bulk perfume bottles neatly and send them to the filling area, laying a good foundation for efficient filling.

Vacuum/normal pressure filling system: According to the characteristics of perfume with strong volatility and high requirements for filling cleanliness and precision, vacuum negative pressure filling is often used to effectively prevent bubbling, overflow or unstable liquid level.

Anti-drip filling head: It adopts stainless steel precision nozzle design with anti-drip and anti-splash functions to ensure that there is no residual liquid contaminating the bottle body during the filling process.

Automatic capping/sprinkler system: automatically places the nozzle, pump head or perfume cap, and completes the precise tightening or pressing operation through the manipulator or capping head.

Intelligent control system (PLC+touch screen): The human-machine interface is intuitive and easy to operate. It can set parameters such as filling volume, speed, error range, and has fault alarm and real-time monitoring functions.

Conveying and lining system: After filling, the bottle enters the labeling, coding or boxing process through the conveyor belt to realize the linkage of the whole line.

2. Advantages of automatic perfume filling machine

High-precision filling: Using servo control or precision flow meter, the filling error can be controlled within ±0.3ml to ensure that the liquid level and appearance of each bottle of perfume are consistent.

Improve production efficiency: multi-head filling system (commonly 4, 6, and 8 heads) supports the output of dozens of bottles per minute, greatly improves the efficiency of the production line, and meets the needs of large-volume orders.

Strong compatibility: It can adapt to a variety of bottle shapes (such as round, square, and special-shaped), bottle mouth sizes, and nozzle types, and flexibly respond to multi-SKU products.

Clean and safe, reducing waste: There are no bubbles or leaks during the filling process, effectively controlling perfume loss, improving product yield, and meeting the quality standards of high-end perfume products.

High degree of automation, saving labor: The fully automatic operation process from bottle sorting to filling and sealing is completed in one go, significantly reducing manual intervention and operating errors.

Today, when the perfume industry increasingly emphasizes quality and efficiency, the automatic perfume filling machine has become an important equipment for many perfume brands and OEM factories to improve productivity and brand image with its comprehensive advantages of precise filling, efficient operation, clean and environmental protection.