Release Date:2025-07-21 11:43:35 Popularity:

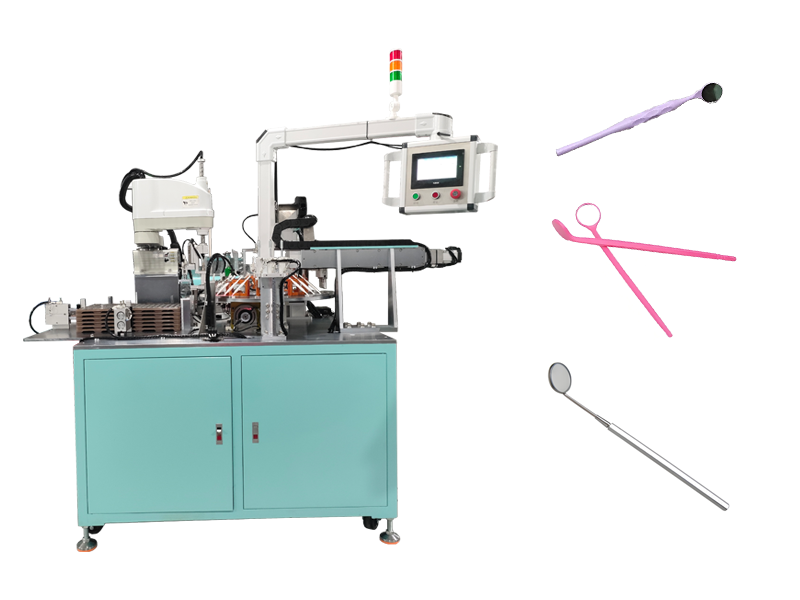

The automatic assembly machine for oral mirrors not only improves production efficiency, but also significantly improves product quality and consistency. As a high-end equipment that integrates automatic feeding, positioning, assembly, and detection, the automatic assembly machine for oral mirrors is gradually becoming a tool for oral mirror manufacturers to improve quality and efficiency.

Oral mirrors, commonly known as dental mirrors, are an indispensable basic tool in dental examinations. They are mainly used by doctors to observe the internal structure of the patient's mouth, reflective lighting, and auxiliary examinations. With the popularization of oral medical services and the promotion of disposable oral mirror products, the market demand for high-quality, large-volume, and high-hygiene oral mirror products continues to grow.

Traditional oral mirror production mostly adopts manual assembly methods, involving the assembly of multiple parts such as mirrors, handles, and connectors. It is not only inefficient, but also has problems such as human errors, high risks of contamination, and high labor costs. For this reason, the introduction of automated equipment has become the key to the development of the industry.

1. The core functions of the automatic assembly machine for oral mirrors

The automatic assembly machine for oral mirrors realizes the automation of the entire process from component feeding to complete machine assembly through modular integrated design. Its main functions include:

Automatic feeding system: Use vibration plate, material channel or manipulator to achieve accurate feeding of each component to ensure continuity and stability.

Positioning and assembly system: The mirror and handle are accurately aligned and assembled through servo system and high-precision positioning module to ensure product consistency and structural firmness.

Ultrasonic or threaded connection system: According to product design, ultrasonic welding or threaded fastening technology can be selected for efficient connection of mirror and handle.

Automatic detection system: Integrate CCD visual detection system or sensor to detect whether the assembled product has looseness, deviation, defectiveness and other problems in real time, and automatically remove defective products.

Finished product output and counting system: Automatically output qualified products and count the number, which is convenient for subsequent packaging or automatic boxing.

2. Equipment advantages

Greatly improve production efficiency: An automatic assembly machine for oral mirrors can achieve an assembly speed of hundreds of pieces per minute, which is far higher than manual efficiency and can meet the needs of rapid delivery of batch orders.

Ensure product consistency and stable quality: Standardized operations during the automated assembly process ensure that the size, firmness, and cleanliness of each product are consistent, reducing human errors.

Reduce manual dependence and reduce operating costs: Only a few operators are required to load and monitor the equipment, which greatly reduces labor costs and management difficulties.

Meet aseptic production requirements: The closed structure and automated process minimize the contact between people and products, and meet the aseptic production standards of disposable medical devices.

Support multiple product compatibility and switching: The equipment is flexible in design, and can quickly replace fixtures and parameter settings according to different models of oral mirrors to achieve diversified product assembly.

The birth and popularization of oral mirror automatic assembly machines marks that the production of oral medical devices has entered a new stage of automation and standardization. It not only solves the pain points of traditional manual assembly, but also brings productivity innovation to the industry. For medical device companies that want to improve their market competitiveness and optimize manufacturing processes, investing in automatic assembly equipment is undoubtedly a strategic choice with long-term returns.