Release Date:2025-07-21 14:51:54 Popularity:

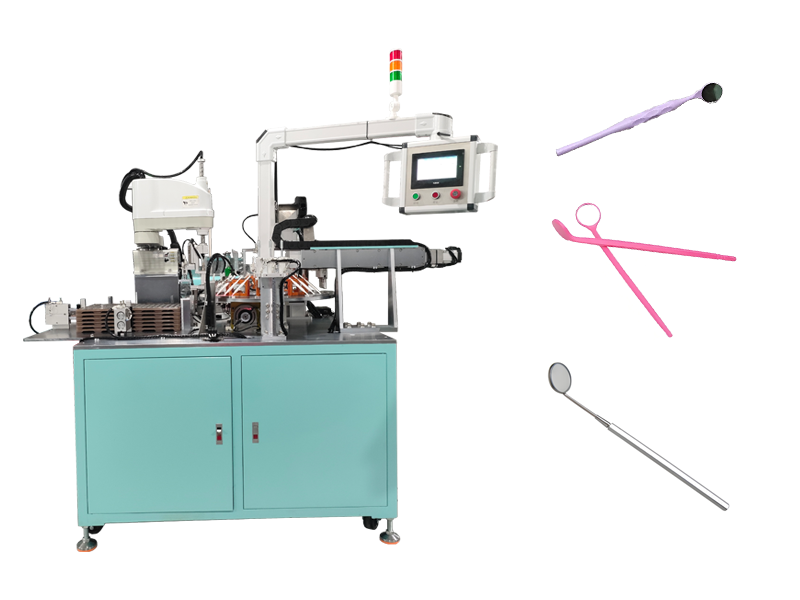

The emergence of dental mirror automatic assembly machine has brought unprecedented changes and value to dental mirror manufacturing companies. Traditional dental mirrors are composed of lenses, mirror handles and connecting structures, and require multiple processes of precision assembly during the production process. With the widespread promotion of disposable dental mirrors and the improvement of global medical and health awareness, the annual market demand for dental mirror products continues to rise, especially in the export field, where customers have higher requirements for product consistency and production efficiency.

1. Working principle of dental mirror automatic assembly machine

Dental mirror automatic assembly machine is a multifunctional automation equipment that integrates automatic feeding, positioning, pressing, screwing, detection and finished product output, designed specifically for dental mirror production. Its core components include:

Automatic feeding system: automatically transport the lens and the handle to the assembly station through a vibration plate or a manipulator;

Precision positioning device: using servo control and visual recognition technology to ensure accurate alignment of the lens and the handle;

Efficient assembly module: thread locking, ultrasonic welding or press-fitting can be used to achieve firm assembly;

Online detection system: built-in CCD vision or sensor, real-time detection of whether the product is assembled in place and whether there are defects;

Finished product delivery and classification: automatically transport qualified dental mirrors to the packaging line, and automatically remove defective products to ensure quality consistency.

2. Equipment advantages and corporate benefits

Significantly improve production efficiency: a dental mirror automatic assembly machine can achieve efficient production of 50 to 100 dental mirrors per minute, far exceeding the production capacity of manual assembly, greatly shortening the delivery cycle, and adapting to the needs of large-volume orders.

Improve product quality stability: automated equipment ensures accurate operation of each link, avoids human errors, and significantly improves product consistency and pass rate.

Save labor costs and management pressure: Traditional manual assembly relies heavily on skilled workers and has high mobility, while automatic assembly machines operate stably and only require a small number of skilled workers for maintenance, greatly reducing labor costs and management complexity.

Meet the clean production requirements of the medical industry: The equipment adopts a closed design and can be operated in a clean workshop, effectively controlling the risk of contamination and meeting the hygiene standards of disposable medical devices.

Compatible with multiple models of products and flexible switching: The automatic assembly machine for dental mirrors can switch modules according to different product designs, support customized production, and is suitable for the assembly needs of dental mirrors of various sizes and structures.

The automatic assembly machine for dental mirrors not only represents the direction of technological upgrading in the field of dental instrument production, but also is a key node for the medical device industry to move towards intelligent manufacturing. It enhances the core competitiveness of enterprises and meets increasingly diverse market needs through efficient, stable, hygienic and precise full-process automated operations.