Release Date:2025-07-30 10:37:09 Popularity:

Customized automation equipment refers to a service process in which automation equipment manufacturers provide personalized design and manufacturing services based on a customer's specific application scenario, product structure, and technical requirements. This type of equipment covers multiple modules, including automated loading, assembly, welding, testing, packaging, and conveying. It can be integrated with MES systems, ERP systems, and even industrial robots, achieving automation and intelligent control throughout the entire production process.

I. Why Choose Customized Automation Equipment

... With labor costs currently on the rise, customized equipment is undoubtedly a highly cost-effective investment.

Enhancing product consistency and traceability: The equipment precisely completes each process through program control, ensuring consistent product quality. Furthermore, intelligent systems collect and record production data for each batch, facilitating quality traceability and data analysis, helping companies build lean management systems.

2. Application Areas of Customized Automated Equipment

Customized automated equipment is applicable to nearly all manufacturing sectors, with particular strengths in the following industries:

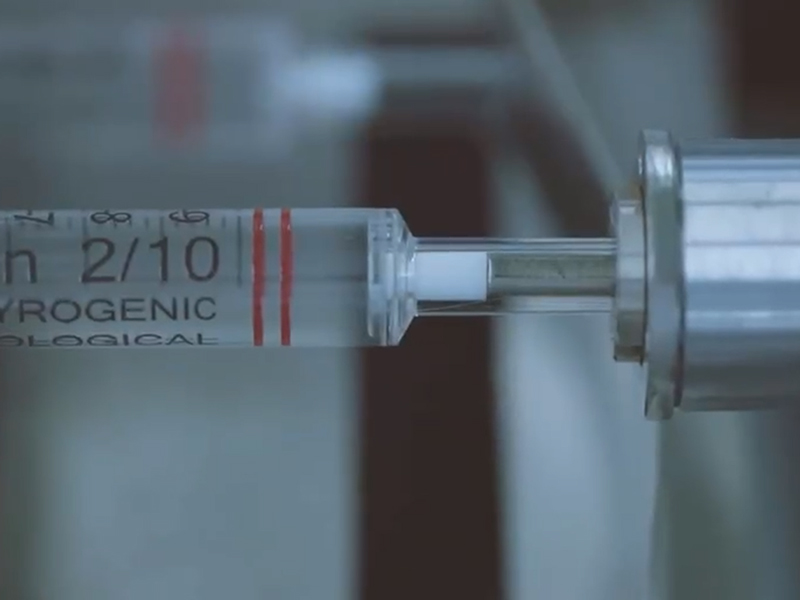

Medical devices: Automated assembly, screen printing, welding, and packaging of medical consumables such as pipettes, test tubes, centrifuge tubes, and culture bottles;

Consumer electronics: High-precision assembly and testing of micro-components such as headphones, camera modules, and connectors;

Hardware and plastic products: Automated hook insertion, welding, flocking, and other functional combination applications;

Food packaging: Quantitative filling and automatic packaging systems for liquids, pastes, and powders;

Household items: Fully automated assembly and surface treatment lines for hangers and trouser racks.

3. Customization Process Analysis

Demand Communication and Site Survey: After the customer identifies production issues and equipment goals, the manufacturer's technical team conducts an on-site inspection of the production site to understand factors such as material properties, process flow, and spatial layout.

Solution Design and Verification Evaluation: Engineers design 3D models and control flow diagrams based on the requirements and verify feasibility through prototype testing or simulation systems to ensure the solution is scientific and reasonable.

Equipment Manufacturing and Commissioning Acceptance: After the equipment is manufactured and commissioned at the factory, it is delivered to the customer's site for installation, joint commissioning, personnel training, and final acceptance.

After-Sales Service and Upgrade Support: We provide ongoing technical support, repair services, and regular maintenance, as well as support for equipment function upgrades and process optimization to meet future development needs.

Automation equipment customization, a key path to driving the transformation and upgrading of the manufacturing industry, has become a crucial means for many companies pursuing efficient production and intelligent manufacturing. Unlike one-size-fits-all solutions based on standardized equipment, customized automation equipment tailors a unique automation system based on a company's product characteristics, production processes, and production capacity requirements. The goal is to maximize production efficiency, reduce labor costs, optimize management processes, and thus enhance the company's overall competitiveness.