Release Date:2025-07-30 11:12:08 Popularity:

As the manufacturing industry continues to upgrade and become more intelligent, companies are increasingly demanding higher standards for production efficiency, product quality, and flexible manufacturing capabilities. Customized automation equipment manufacturers, serving as a crucial bridge between companies' production needs and high-end manufacturing solutions, are increasingly attracting market attention. Compared to traditional standard equipment, customized automation equipment can provide tailored solutions tailored to a company's specific product structure, production process, and production capacity requirements, helping them achieve automated and intelligent production upgrades.

1. What is a Customized Automation Equipment Manufacturer?

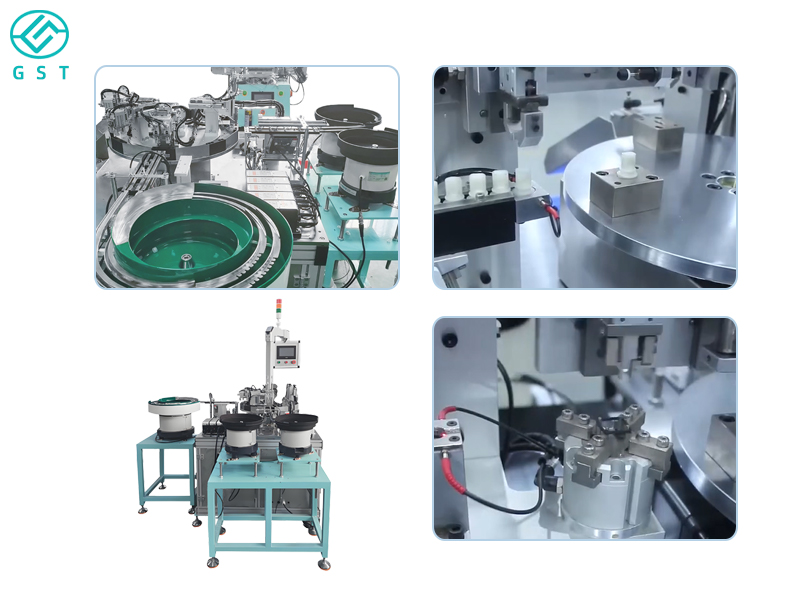

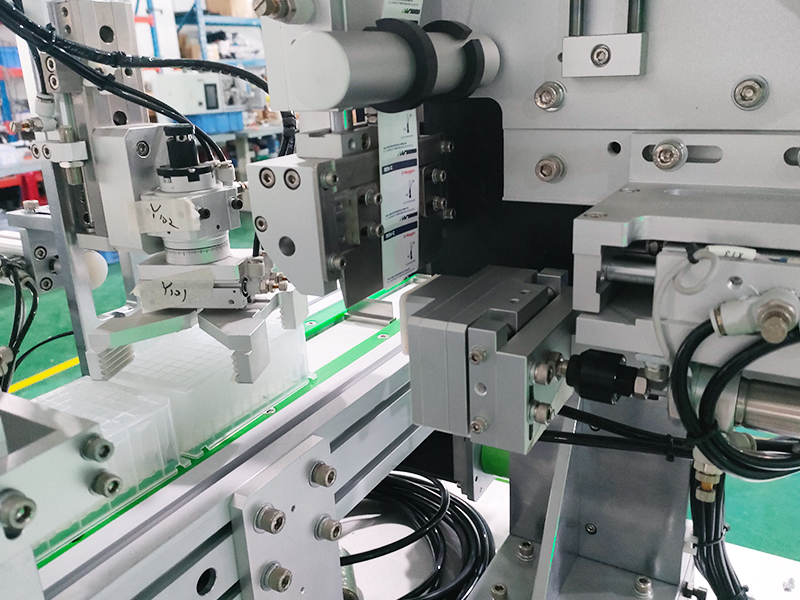

Customized automation equipment manufacturers are technology companies that specialize in the design, manufacture, commissioning, and service of custom-designed automation equipment. These manufacturers typically possess strong R&D capabilities, engineering design experience, project management, and manufacturing integration capabilities. They are able to develop customized production equipment systems tailored to the specific needs of individual customers, achieving automation, efficiency, and intelligence in all production processes.

Unlike standard equipment suppliers, customized automation equipment manufacturers do not provide off-the-shelf products. Instead, they deeply understand customer needs, design the equipment structure from scratch, select the appropriate control system and actuators, and provide integrated solutions tailored to the customer's specific production lines.

2. Core Advantages of Custom Automation Equipment Manufacturers

Highly Compatible with Practical Needs: Every factory's product mix, process flow, production line layout, and degree of automation vary. Custom automation equipment manufacturers can precisely tailor equipment to meet your company's specific pain points, helping them achieve true "use, performance, and long-term" performance.

Flexible Compatibility with High-Variety, Small-Batch Demand: With high-variety, customized production becoming increasingly mainstream, standard equipment struggles to meet the demands of flexible production. Custom automation manufacturers, however, can develop modular, adjustable automation equipment to accommodate rapid production switching across multiple products.

Improving Efficiency and Reducing Costs: By reorganizing process flows and automating equipment design, customized equipment can significantly increase productivity per unit time, reduce labor input, and lower error rates, thereby lowering overall production costs over the long term.

Supporting Digital and Intelligent Integration: Excellent custom automation equipment manufacturers not only focus on mechanical structure but also integrate visual recognition, PLC control, robotic collaboration, data acquisition, and MES systems into their equipment, enabling them to achieve "intelligent perception + intelligent execution + intelligent management" capabilities.

3. Custom Automation Equipment Manufacturers Have Wide Applications

Almost all manufacturing industries may require customized automation equipment, including but not limited to:

Medical consumables industry: Equipment for automated assembly, capping, screen printing, and welding of pipettes, centrifuge tubes, and culture bottles;

Hardware and plastic products: Complete lines for automated flocking, hook insertion, glue removal, and assembly of hangers and trouser racks;

Food and daily chemical industry: Automatic filling, packaging, and sealing equipment for sauces, beverages, facial creams, and toothpaste;

Consumer electronics industry: Automated production lines for component placement, testing, and assembly;

New energy and automotive parts: Power battery module assembly lines, automatic motor testing lines, etc.

4. How to Choose a High-Quality Custom Automation Equipment Manufacturer

Technical Strength and R&D Capabilities: Review the manufacturer's engineering team size, patented technologies, number of successful cases, and industry experience, particularly their capabilities in visual recognition, control system development, and mechanical structure design.

Service Response Speed and Project Management Capabilities: A mature custom manufacturer should be able to quickly respond to customer needs, develop feasible plans, deliver projects on time, and provide long-term after-sales service.

Customer Reputation and Case Studies: Customers' actual experience and reputation are the most reliable evaluation criteria. Whether a manufacturer has provided equipment to well-known industry brands, listed companies, or foreign-funded enterprises is a key indicator of its strength.

Innovation Capabilities and Flexible Production Support: Whether the equipment is upgradeable, supports product switching, and has data integration capabilities is crucial to a company's future development potential.

Customized automation equipment manufacturers are not only powerful drivers of transformation and upgrading for modern manufacturing companies, but also crucial partners in achieving quality and efficiency improvements. Faced with fierce market competition and ever-changing customer demands, companies can only succeed in the future manufacturing landscape by optimizing processes and maximizing efficiency through professional customized automation equipment solutions. Choosing a capable and experienced customized automation equipment manufacturer is a crucial step towards intelligent manufacturing.