Release Date:2023-07-07 09:48:34 Popularity:

With the continuous advancement of science and technology and the rapid development of the manufacturing industry, non-standard automated production lines, as an important part of modern production methods, are gradually becoming a key means for enterprises to improve production efficiency and reduce costs. This article will introduce the concept, advantages and significance in practical application of non-standard automated production lines, aiming to provide readers with an in-depth understanding and mastery of knowledge in this emerging field.

A. The concept of non-standard automated production line

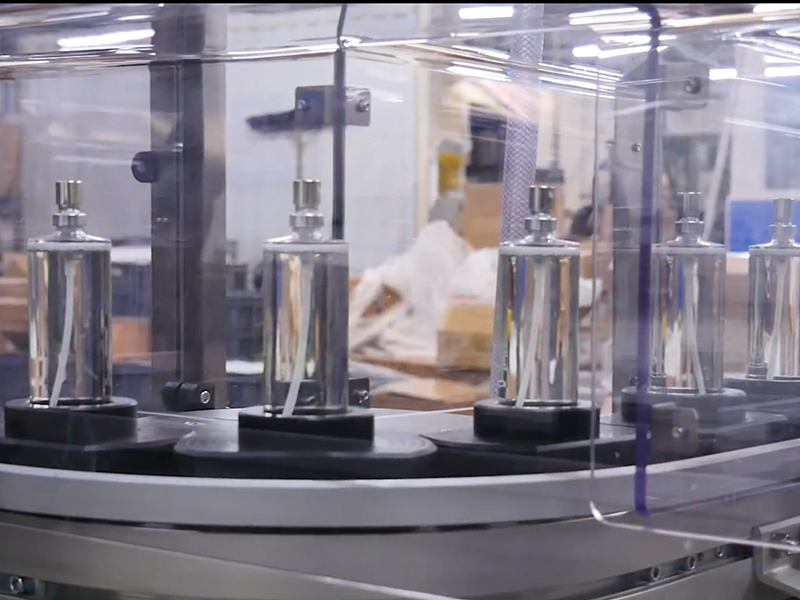

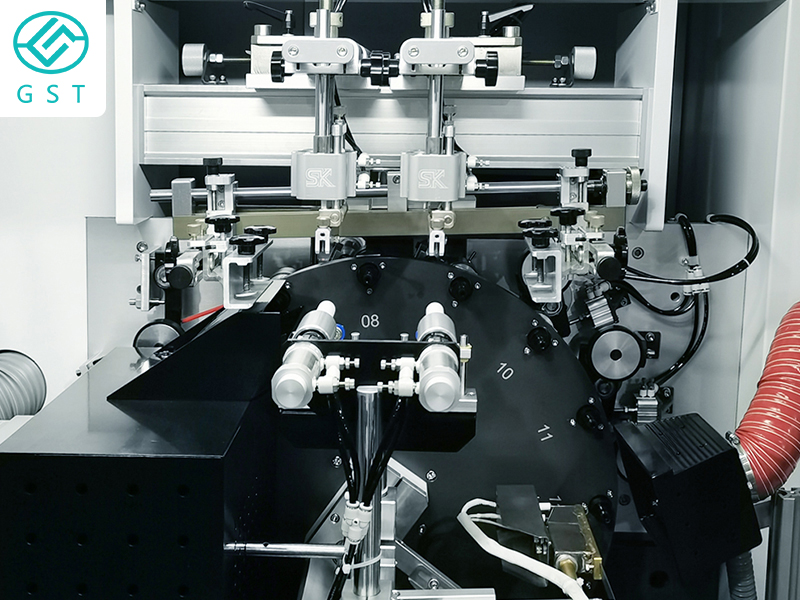

Non-standard automated production line refers to a customized production line composed of automation equipment, sensors, robots and control systems according to the production needs of a specific enterprise. Compared with traditional standardized production lines, non-standard automated production lines are more flexible and intelligent, and can be individually designed and optimized according to product characteristics and production processes.

B. Advantages of non-standard automated production lines

1. Improve production efficiency: The non-standard automated production line realizes a high degree of automation and continuous production by reducing human intervention and optimizing the production process. It can greatly improve production efficiency, reduce production cycle, increase output, and can maintain stability under high load and long-term operation.

2. Reduce production costs: Through the application of non-standard automated production lines, enterprises can reduce manual operations and labor costs, and reduce error rates and scrap rates in production. In addition, non-standard automated production lines can also optimize material flow and resource utilization, further reducing waste of raw materials and energy.

3. Improve product quality: Non-standard automated production lines are highly accurate and repeatable, can reduce errors caused by human operations, and can monitor and control all links in the production process in real time. This makes the quality of the product more stable, reduces variations and defects in production, and improves customer satisfaction and corporate reputation.

4. Adapt to multi-variety and small-batch production: traditional standardized production lines are usually suitable for large-scale and high-volume production, while non-standard automated production lines are more suitable for multi-variety and small-batch production models. It can quickly adjust configurations and parameters to adapt to rapid changes in market demand, providing a more flexible and responsive production method.

C. Practical application significance of non-standard automated production lines

Non-standard automated production lines are widely used in many industries, such as automobile manufacturing, electronic equipment, medical equipment, etc. They provide businesses with numerous benefits, including:

1. Transformation and upgrading of the manufacturing industry: non-standard automated production lines help to improve the competitiveness and innovation capabilities of traditional manufacturing industries, and promote the development of enterprises in the direction of intelligence, digitalization, and flexibility, so as to adapt to the rapid changes in the market and individual needs.

2. The ideal realization of human-machine collaboration: the non-standard automated production line combines human wisdom with machine precision, and realizes a more efficient production method through human-machine collaboration. Workers can be freed from single repetitive labor and turn to more advanced tasks, such as quality control, fault diagnosis, etc., to further improve overall production efficiency.

3. Save resources and protect the environment: Non-standard automated production lines can optimize the use and recycling of materials, reduce energy consumption, and effectively reduce the impact on the environment. Through refined management and monitoring, environmental pollution such as waste water and exhaust gas emissions can be better controlled and reduced.

The non-standard automated production line is a customized production method, which has the advantages of improving production efficiency, reducing costs, improving product quality, and adapting to multi-variety and small-batch production. It brings new possibilities for enterprises to realize manufacturing transformation and upgrading, human-machine collaboration and resource and environmental protection. In the future development, non-standard automated production lines will continue to play an important role, leading the manufacturing industry to develop in a more intelligent and sustainable direction.