Release Date:2023-07-08 09:35:15 Popularity:

With the continuous development of industrialization and automation technology, fully automatic packaging production lines play an increasingly important role in modern manufacturing. With its high efficiency, precision and reliability, the fully automatic packaging production line has become an ideal choice for many enterprises to maximize production efficiency. This article will introduce the concept and application of fully automatic packaging production line, discuss its impact on enterprise production efficiency and product quality, and look forward to the future development trend of fully automatic packaging production line.

A. Concept and composition of fully automatic packaging production line

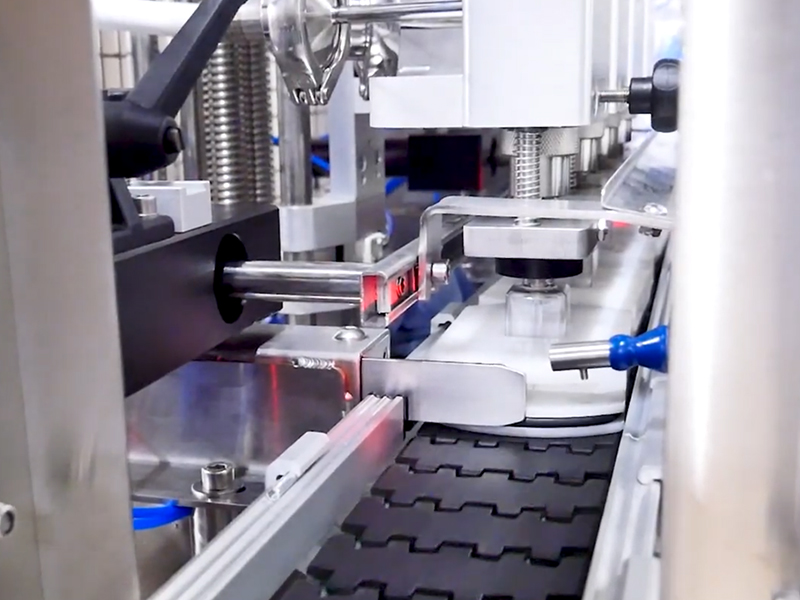

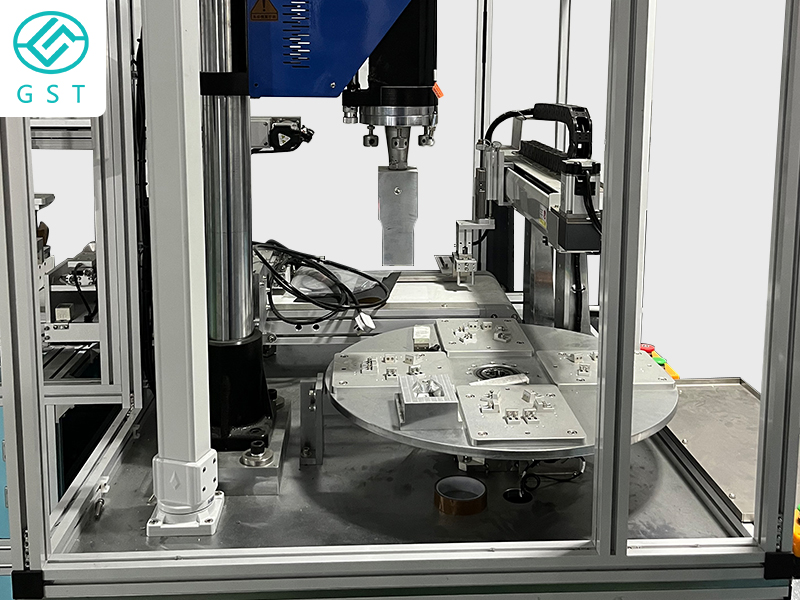

Fully automatic packaging production line refers to a production line that realizes a series of operations such as product packaging, stacking and shipment through automated equipment and systems. It usually consists of multiple components such as conveying system, packaging machinery, testing equipment and control system. The packaging requirements of different industries and products are quite different, so the specific configuration and process flow of the automatic packaging production line will be different.

B. Advantages of fully automatic packaging production line

1. Improve production efficiency: The fully automatic packaging production line can realize rapid and continuous completion of packaging operations, greatly improving production efficiency. Compared with the traditional manual packaging method, the fully automatic packaging production line can save a lot of human resources, and in the case of 24-hour continuous operation, there is almost no downtime for maintenance, and the production efficiency is higher.

2. Guarantee product quality: The fully automatic packaging production line has a high degree of accuracy and stability, and can accurately package products, avoiding the impact of human factors on packaging quality. Through the application of advanced testing equipment and quality control system, accurate monitoring of product size, weight, appearance, etc. can be realized, thereby ensuring the quality and consistency of products.

3. Reduce packaging costs: The fully automatic packaging production line can realize automatic and precise control during the packaging process, and achieve the best packaging effect by optimizing the packaging layout and material utilization, thereby reducing packaging costs. In addition, through automated logistics management and scheduling, other costs such as manpower and time can also be reduced.

4. Improve safety: In the fully automatic packaging production line, operators have less contact with dangerous environments and equipment, which effectively reduces the occurrence of accidents. The automatic control system can monitor the operating status and faults of the equipment in real time, and take corresponding safety measures to improve the safety of the production line.

C. The future development trend of fully automatic packaging production line

1. Intelligence: With the continuous development of artificial intelligence technology, the fully automatic packaging production line will become more intelligent. For example, through image recognition and deep learning algorithms, automatic sorting and classification of products, automatic adjustment of packaging parameters and other functions are realized, making the production line have a higher level of intelligence.

2. Flexibility: The future fully automatic packaging production line will be more flexible and able to adapt to diverse product and packaging needs. Through the quick-change technology and the design of the adjustment mechanism, the production line can complete product packaging of different specifications, shapes and sizes in a relatively short period of time, improving production efficiency and adaptability.

3. Energy saving and environmental protection: The design and material selection of fully automatic packaging production lines pay more and more attention to energy saving and environmental protection. For example, adopt efficient motor drive system, waste recycling system and energy-saving transmission equipment, etc., to reduce energy consumption and waste discharge, and reduce the impact on the environment.

4. Man-machine collaboration: The future fully automatic packaging production line will pay more attention to man-machine collaboration. Automated equipment and robots will work closely with operators to complete the packaging operations. Through reasonable man-machine interface design and training, the skill level and participation of operators can be improved, and the optimized operation of the production line can be realized.

With its high efficiency, precision and reliability, the fully automatic packaging production line has become an indispensable part of the modern manufacturing industry. It plays an important role in the production process of enterprises by improving production efficiency, ensuring product quality, reducing packaging costs and improving safety. In the future, the fully automatic packaging production line will be more intelligent, flexible, energy-saving, environmentally friendly and human-machine collaboration, providing enterprises with more efficient and sustainable packaging solutions. It is believed that with the continuous advancement of technology, the fully automatic packaging production line will surely lead the future development of the packaging industry.