Release Date:2023-09-24 10:03:55 Popularity:

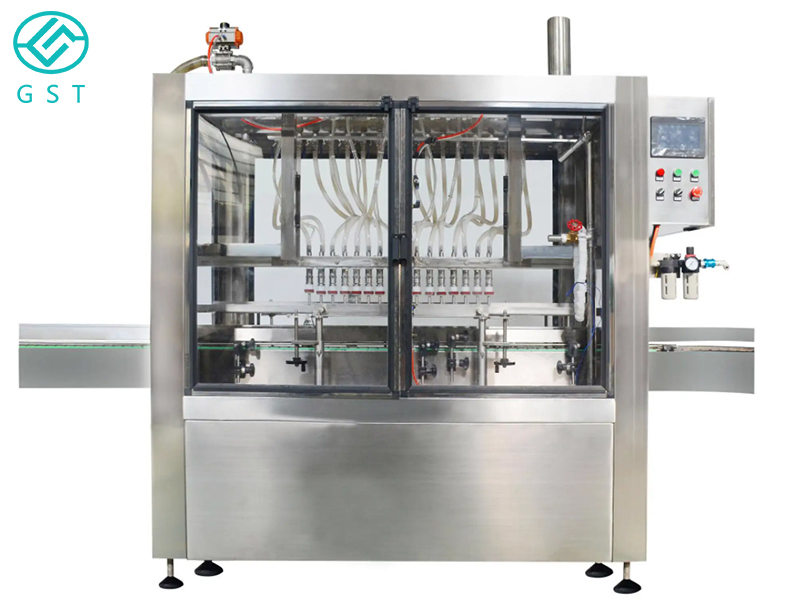

In today's highly competitive market environment, improve production efficiency, reduce costs and ensure product quality has become an important goal for every enterprise. As an advanced production tool, automatic filling equipment plays a vital role in this regard. In this paper, we will introduce the advantages of automatic filling equipment, application scenarios and practical considerations to help companies better understand and utilize this important production tool.

Automatic filling equipment background and current development With the continuous development of science and technology, automation has become an indispensable element of the modern production process. Automatic filling equipment is a modern filling equipment in this context. At present, the global market for automatic filling equipment continues to grow, and more and more companies are beginning to adopt this highly automated filling method to improve production efficiency and reduce costs.

Advantages of automatic filling equipment Automatic filling equipment has the following advantages:

Improve production efficiency: automatic filling equipment can realize 24-hour uninterrupted work, greatly improving production efficiency and shortening the time to market.

Reduce costs: the adoption of automatic filling equipment reduces manual intervention, reducing labor costs, while simplifying the production process, reducing production costs.

Improve product quality: automatic filling equipment adopts precise measurement and control system, which can ensure that the weight and quality of each batch of products remain consistent, improving product quality and stability.

Application Scenarios of Automatic Filling Equipment Automatic filling equipment is widely used in the following industries:

Beverage industry: Beverage manufacturers use automatic filling equipment to quickly and accurately complete the filling and sealing of beverages, improving production efficiency and product quality.

Food industry: food manufacturers use automatic filling equipment can efficiently complete the filling and packaging of various types of food, improve production efficiency and product hygiene and quality.

Chemical industry: chemical enterprises use automatic filling equipment can realize the accurate filling and transportation of dangerous chemicals, improve production efficiency and safety.

Precautions for the actual operation of automatic filling equipment When operating automatic filling equipment, you need to pay attention to the following matters:

Equipment installation and commissioning: When installing and commissioning the automatic filling equipment, you need to make sure that the equipment is in a horizontal position, and adjust the height and position of the import and export of the equipment to ensure that the equipment operates normally.

Pre-operation inspection: Before starting to operate the automatic filling equipment, you need to check the various parts of the equipment, especially the seals, lubrication parts of the equipment, etc. to ensure the safety of the equipment.

Operation specification: in the operation of automatic filling equipment, you need to strictly comply with the operating specifications of the equipment, in accordance with the procedures of the equipment, to avoid damage to the equipment or affect the production due to misuse.

Maintenance: automatic filling equipment requires regular maintenance to ensure the normal operation and service life of the equipment. For example, you need to regularly check the wear parts of the equipment, clean the surface of the equipment, replace the seals.

Safety awareness: the operation of automatic filling equipment personnel need to have safety awareness, to avoid equipment failure or misuse of safety accidents. For example, in the operation process, you need to avoid putting your hands inside the equipment, avoid placing debris near the equipment.

In general, automatic filling equipment is a modern production tool with significant advantages, can improve production efficiency, reduce costs, improve product quality, and widely used in beverage, food, chemical and other industries. In the actual operation process, you need to pay attention to the installation and commissioning of the equipment, pre-operation checks, operational specifications, maintenance and safety awareness, in order to ensure the normal operation of the equipment and production safety. With the continuous development of science and technology, I believe that automatic filling equipment will play a more important role in the future production field.