Release Date:2023-09-24 10:41:07 Popularity:

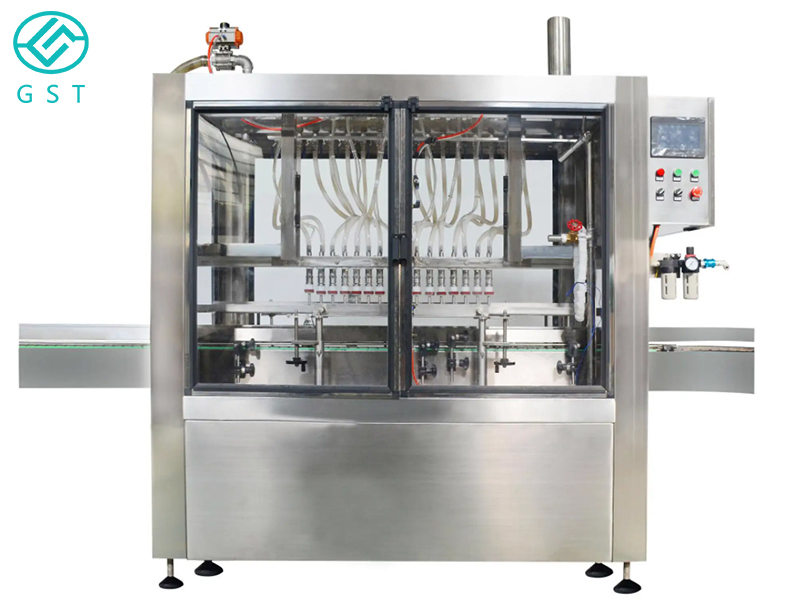

In today's highly automated industrial production environment, automatic filling equipment has become a must-have for all major manufacturing companies. This equipment greatly improves production efficiency, reduces production costs, but also significantly improves product quality. In this paper, we will analyze the development of automatic filling equipment background, advantages, application scenarios, as well as practical operation, in order to give readers a deeper understanding of this important tool.

First, the background of automatic filling equipment

With the increasingly fierce competition in the market, production enterprises to improve production efficiency and reduce costs of the increasingly strong demand. In this context, automatic filling equipment came into being. Initially, the equipment is mainly used for the production of beverage industry, and later gradually expanded to food, chemical and other industries. Today, automatic filling equipment has developed into a large family, including a variety of models and specifications to meet the needs of different industries and different sizes of enterprises.

Second, the advantages of automatic filling equipment

Improve production efficiency: automatic filling equipment can continuously and quickly complete the filling operation, greatly improving production efficiency. Compared with the traditional manual filling method, automatic filling equipment can complete a large number of products in a short period of time filling, and strongly enhance the production capacity of enterprises.

Reduce costs: the use of automatic filling equipment can significantly reduce labor costs. On the one hand, the automatic filling equipment can replace the manual completion of repetitive filling work, reducing the labor intensity of workers; on the other hand, the automatic filling equipment can be in extreme circumstances for continuous work, thus reducing the dependence on human resources.

Improve product quality: automatic filling equipment adopts precise metering and control system, which can ensure that each product can be accurately filled. Avoid problems caused by human factors such as uneven filling or overflow of products, thus significantly improving product quality.

Third, the application of automatic filling equipment

Beverage industry: automatic filling equipment in the beverage industry is the most widely used, from pure water, mineral water to juice, drinks and other types of beverage filling can see its figure.

Food industry: automatic filling equipment is also widely used in the food industry, such as all kinds of sauces, condiments, edible oil filling.

Chemical industry: many products in the chemical industry, such as paint, ink, pesticides, etc., also need to use automatic filling equipment for mass production and filling.

Fourth, the actual operation of automatic filling equipment

The actual operation of automatic filling equipment, first of all, according to the instructions for the use of equipment for accurate parameter settings, including filling volume, filling speed and so on. After starting the equipment, just make sure that the equipment is in normal operating condition, while paying attention to regular maintenance and repair equipment to ensure its normal operating efficiency. In the actual operation process, safety is crucial, and need to strictly follow the safety operating procedures provided by the equipment manufacturer.

Automatic filling equipment as a modern industrial production of key equipment, its importance is self-evident. It not only significantly improves production efficiency, reduces production costs, but also provides a strong guarantee for the improvement of product quality. Looking ahead, with the continuous development of science and technology, automatic filling equipment is expected to be used in more industries, the market has broad prospects.

In general, automatic filling equipment is undoubtedly the ideal choice for enterprises to improve competitiveness and optimize production processes. For enterprises seeking to improve production capacity and product quality, automatic filling equipment is undoubtedly a sharp tool, worthy of corporate investment and attention.