Release Date:2023-09-25 11:49:05 Popularity:

In the manufacturing industry, a filling machine is an essential piece of equipment that is capable of pouring liquid or semi-liquid products into containers to fulfill different needs in the production process. The manual filling machine, as a member of the filling machine family, has become the right-hand man in the production process of enterprises in some specific scenarios due to some of its unique advantages. In this article, we will discuss the manual filling machine, take you to understand its characteristics, working principle, application scenarios, as well as the existence of problems and solutions.

First of all, the manual filling machine has the advantages of high productivity and simple operation. Compared with automatic filling machines, manual filling machines do not require complex pneumatic or electric systems, and only need to complete the filling process through simple manual operation. This makes it particularly flexible in some small batch, multi-variety production process. In addition, the manual filling machine on the operator's skills requirements are low, only after a simple training can start, greatly reducing the cost of labor.

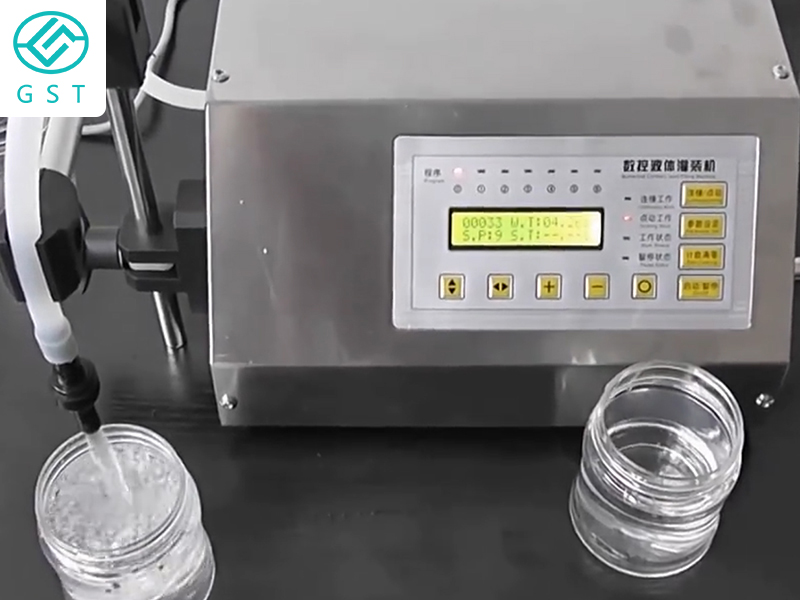

Next, we come to a detailed understanding of the working principle and components of the manual filling machine. Manual filling machine is mainly composed of filling head, quantizer, cylinder and conveyor belt. The filling head is the core component of the equipment, which is responsible for pouring liquid or semi-liquid products into the container. The doser is responsible for controlling the filling volume, while the cylinder provides the power to push the filling head to carry out the filling operation. The conveyor belt is responsible for transporting the container to the designated location to complete the entire filling process.

In terms of application scenarios, manual filling machines are widely used in pharmaceutical, food, daily chemical and many other industries. For example, in the pharmaceutical industry, manual filling machine is often used for filling drugs, reagents and other liquid products; in the food industry, it is used for filling spices, edible oil and other semi-liquid products; in the daily chemical industry, manual filling machine is used for filling shampoo, shower gel and other products.

However, manual filling machines also have some problems. First of all, because it is manually operated, so the operator's physical strength requirements are high, and prolonged operation can easily lead to fatigue. Secondly, the productivity of manual filling machine is relatively low, which can not meet the needs of mass production. For these problems, the following measures can be taken to solve them:

Equipment maintenance and maintenance: in order to ensure the normal operation of the manual filling machine, enterprises need to develop appropriate equipment maintenance and maintenance programs. Regular cleaning, lubrication and inspection of equipment to extend the service life of the equipment and reduce the failure rate.

Optimization of the operating process: through the optimization of the operating process, reduce the physical consumption of the operator. For example, the layout of the conveyor belt can be improved so that the operator does not have to frequently bend and lift heavy objects and other actions.

Increase automation elements: Although the manual filling machine mainly relies on manual operation, but companies can try to introduce some automation elements to improve production efficiency. For example, you can add photoelectric sensors, counters and other automation devices to achieve automatic control and counting functions.

Improve the skills of operators: strengthen the skills training of operators so that they can master the operating skills and precautions of manual filling machines. This not only improves productivity, but also reduces the safety risks caused by improper operation.

In short, manual filling machine as a flexible, practical filling equipment, in the production of enterprises play an irreplaceable role. By understanding the characteristics of the manual filling machine, working principle, application scenarios, as well as the existence of problems and solutions, enterprises can better choose and use the manual filling machine, improve production efficiency and reduce costs, for the upgrading and development of the manufacturing industry to help.