Release Date:2023-09-25 11:07:57 Popularity:

Production automation assembly line refers to the production process through automated equipment and information systems, the integration of various links in the production process, to achieve the continuity and efficiency of the production process. In modern industrial production, production automation assembly line has become an important development direction of manufacturing industry. This paper will introduce the concept, characteristics, design ideas and realization of production automation assembly line, and analyze its application prospects in industrial production.

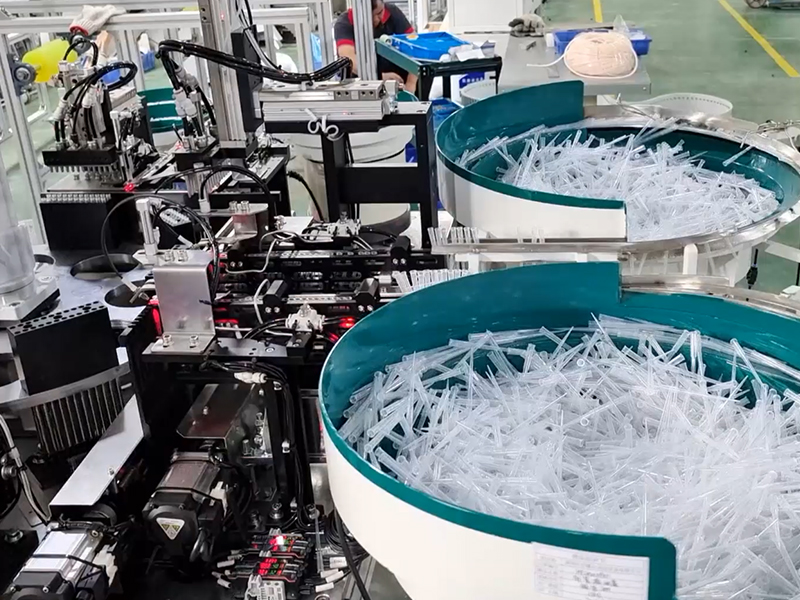

Production automation assembly line refers to the use of automation equipment, robots, computer control systems and other means in the production process, to achieve the automatic transportation of raw materials, processing, testing, packaging and other aspects of the continuous flow. Production automation assembly line has the following characteristics:

High efficiency: automated assembly line can greatly improve production efficiency, reduce labor and material costs, and improve enterprise competitiveness.

Stable quality: the production process of the automated assembly line is strictly controlled, reducing the impact of human factors on product quality and improving the stability and consistency of product quality.

Flexibility: automated assembly line can quickly adjust the production mode according to the market demand, to meet the production needs of different products.

Labor saving: automated assembly line can reduce a large number of repetitive labor, reduce the labor intensity of workers and improve production safety.

The realization of production automation assembly line needs to be considered from the following aspects:

Process design: According to the production demand of the product, formulate the production flow and process route, and clarify the parameters and requirements of each link.

Equipment selection: according to the production process and process requirements, select the appropriate automation equipment and robots, to ensure the accuracy and stability of the equipment.

System Integration: Integrate various automation equipment and information system to realize the interaction and sharing of information and improve production efficiency.

Personnel training: the implementation of production automation assembly line requires operators to have the appropriate skills and qualities, so the need for staff training and skills upgrading.

Production automation assembly line in industrial production has a wide range of application prospects. For example, the automobile manufacturing industry is one of the most mature application of automated assembly line. From the processing and assembly of parts and components to the inspection and packaging of the entire vehicle, the automated assembly line runs through the entire production process. In addition, electronics, pharmaceuticals, chemicals and many other industries are also gradually promoting and applying automated assembly line technology to improve production efficiency and product quality.

With the continuous progress of technology and the expansion of the scope of application, the development potential of production automation assembly line will be even more enormous. In the future, the automated assembly line will develop in the direction of more intelligent, flexible and networked. Intelligent means that the equipment has higher self-adaptive ability and self-decision-making ability, and can be automatically adjusted and optimized according to the actual situation in the production process. Flexibility refers to the ability of equipment to adapt to different products, different specifications of the production needs, improve production flexibility. Networking refers to the depth of integration of various equipment and systems, to achieve comprehensive interaction and sharing of information to improve production efficiency and quality.

In short, production automation assembly line is an important development direction of modern industrial production. It has the characteristics of high efficiency, stable quality, flexibility and labor saving, which can improve the productivity and competitiveness of enterprises and promote the sustainable development of industrial production. With the continuous progress of technology and the expansion of the scope of application, the development potential of production automation assembly line will be even more enormous, and bring a better prospect for the future of industrial production.