The online chipless tube cutting machine is a highly efficient cutting device specifically developed for manufacturers of plastic tubes, laboratory consumables, and medical consumables. Utilizing ad

The online chipless tube cutting machine is a highly efficient cutting device specifically developed for manufacturers of plastic tubes, laboratory consumables, and medical consumables. Utilizing advanced online cutting technology, it enables continuous, precise, and chipless cutting during the tube production process. Compared to traditional cutting methods, the online chipless tube cutting machine not only produces smooth, burr-free, and debris-free cuts, but also effectively avoids secondary cleaning and contamination, significantly improving production efficiency and product quality.

Core Advantages:

Chipless Cutting: Utilizing specialized cutting tools and cutting methods, the cuts are smooth and neat, leaving no residual chips.

High-Precision Control: Equipped with a servo motor and intelligent control system, the cutting process is precise, with an error of less than ±0.1mm.

Online Production: Can be directly connected to production equipment such as extruders and stretchers for fully automated continuous cutting.

Improved Efficiency: Fast cutting speeds and high production capacity make it suitable for large-scale production.

Wide Applicability: Suitable for plastic tubes of various materials and specifications, supporting customized requirements.

Applications:

Medical consumables industry: Cutting pipettes, cryogenic tubes, reagent tubes, and other tubing.

Laboratory consumables production: Suitable for standardized cutting of a variety of laboratory plastic tubing.

Plastic tubing processing: Chip-free cutting of small-diameter tubing such as PE, PP, and PVC.

Other precision tubing industries: Suitable for applications requiring strict cut flatness and cleanliness.

Technical Features:

Intelligent PLC control system for easy operation, supporting quick parameter adjustment and saving.

Long tool life and low maintenance costs.

Vibration-free cutting ensures consistent finished tubing.

Optional automatic collection and inspection module enables unmanned operation.

The pipe cutting machine is used to cooperate with the extruder on the extruded pipe or alone on the high-precision pipe cutting operations, matching the speed of the extruder to the PS pipe fixed-length cutting, precision up to ± 0.1mm.

Applicable pipes:

Various caliber tubes, hose cutting, hose cutting, foam tube cutting, thin metal tube, hard material hose (need to change the knife) water hose, air hose and so on. Can also be customized for special shapes of tubes.

Equipment features:

1) Automatic cutting and discharging.

2) Cutting out of the product automatically drop material.

3) Adopting circular knife rotary cutting, high cutting precision, tolerance ± 0.1mm.

4) The standard parts of the machine adopt imported brands.

5) All the parts adopt special treatment, durable and delicate.

Technical Parameters:

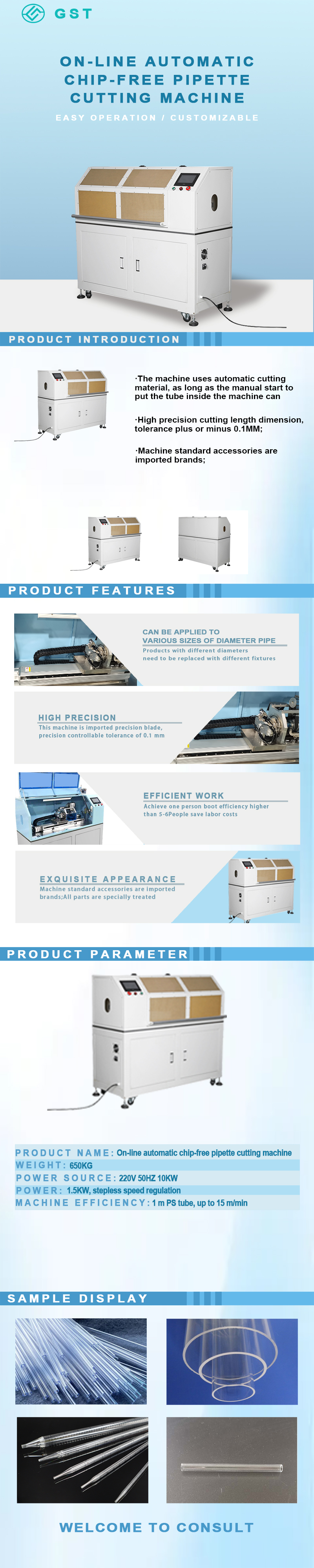

Equipment Model: GST-YYG100A

Pipette capacity: 1-100ml

Cutting efficiency: 1 meter tube, can reach 15 meters / min

Cutting precision: tolerance ± 0.1mm

sizes: 2600*600*1700mm

production capacities: 15m/min for 1 meter pipe

power (output): 1.5KW

Customized Support: Yes