The multifunctional blister packaging machine is an automated packaging machine that integrates thermoforming, automatic loading, sealing, and cutting functions. It is widely used in the food, pharm

The multifunctional blister packaging machine is an automated packaging machine that integrates thermoforming, automatic loading, sealing, and cutting functions. It is widely used in the food, pharmaceutical, laboratory consumables, electronics, and daily necessities industries. Utilizing advanced blister forming technology, this machine rapidly processes plastic sheets such as PVC, PET, and PP into the desired shape, then precisely bonds them to the product, resulting in safe, aesthetically pleasing, and standardized packaging.

Core Advantages:

Multi-Function Integration: A single machine performs forming, loading, sealing, and cutting, minimizing manual intervention.

High Efficiency: Continuous operation and high production speeds make it suitable for large-volume production.

Intelligent Control: Equipped with a PLC control system and touchscreen interface, it allows for easy parameter settings and supports switching between multiple specifications.

Beautiful Packaging: Clear forming and tight sealing enhance the product's market image and added value.

Cost Savings: Reduces labor input, lowers production costs, and improves the yield rate of finished products.

Applications:

Food Industry: Individual blister packaging for chocolate, candy, dried fruit, baked goods, etc.

Medical and laboratory consumables: Safe packaging for disposable consumables such as syringes, pipettes, tips, and reagent tubes.

Electronic products: Transparent packaging for small electronic accessories such as headphones, data cables, and batteries.

Daily necessities: Retail packaging for toys, stationery, and hardware accessories.

Technical Features:

A high-performance heating system ensures uniform heating of plastic sheets and stable molding results.

Equipped with a servo motor drive to ensure precise molding and cutting.

Automatic loading and unloading is supported, reducing manual intervention.

Customizable molds can be tailored to meet customer needs, allowing for flexible adaptation to different products.

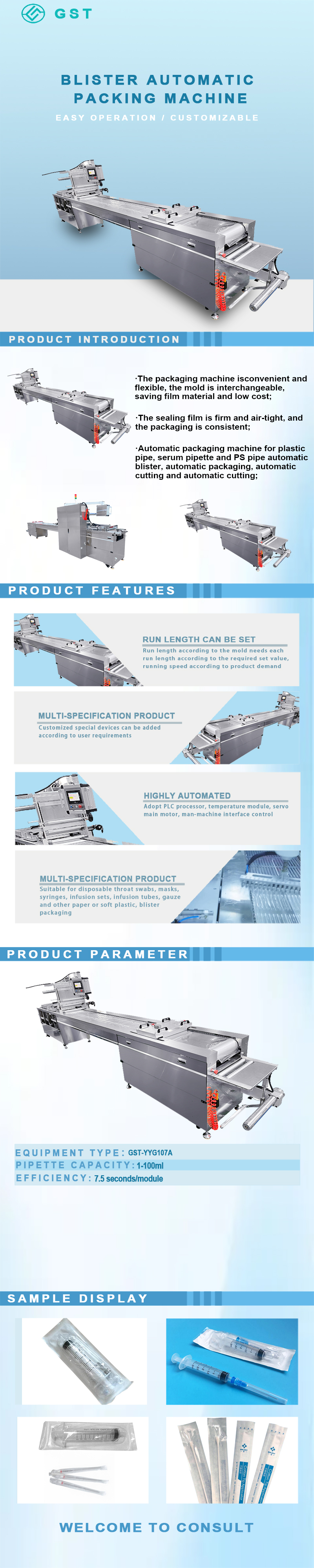

This automatic blister packing machine can perform automatic blistering, automatic packing, automatic slitting and automatic discharging for plastic tubes, serum pipettes, PS tubes.

Equipment features:

1) Packaging machine is convenient and flexible, the mold is interchangeable and universal; 2) Film material saving, low cost; 3) Seal the film firmly without air leakage, consistent packaging.

Technical parameters:

Equipment Model: GST-YYG107A

Pipette capacity: 1-100ml

sizes: L6000*W900*H1800mm

production capacities: 7.5 seconds/module

power (output): 380VAC

Customized Support: Yes