The stool test tube automatic assembly machine is a highly efficient automated device developed specifically for companies producing medical testing reagents and consumables. It is primarily used fo

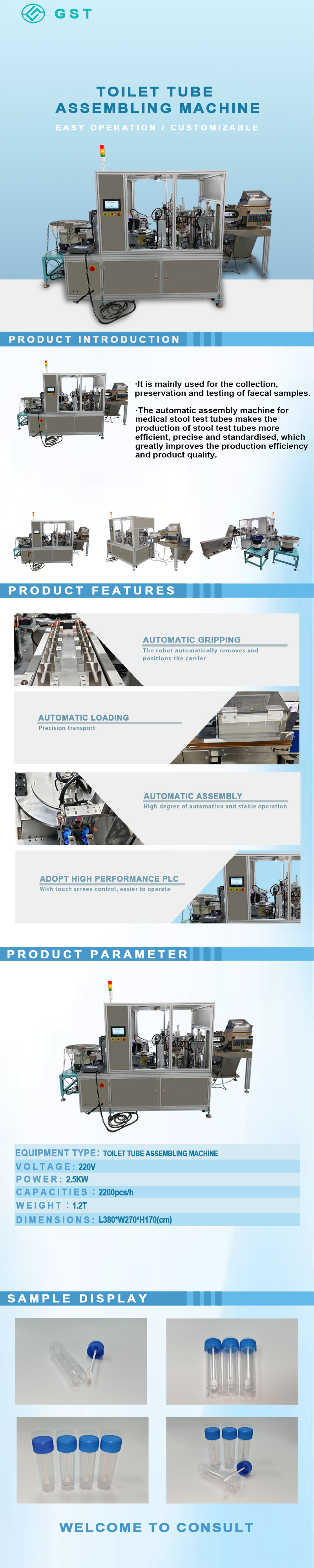

The stool test tube automatic assembly machine is a highly efficient automated device developed specifically for companies producing medical testing reagents and consumables. It is primarily used for the automated assembly, testing, and packaging of stool test tubes. The machine precisely loads and automatically assembles the tube body, cap, spoon, and other components. Combined with an intelligent inspection system, it achieves a highly efficient and standardized production process, significantly reducing labor costs and improving product consistency and cleanliness.

Core Advantages:

Efficient Production: Fully automated loading and assembly significantly increases production capacity to meet the demands of large-volume orders.

Precise Assembly: Servo motor drive and an intelligent control system ensure precise assembly of each component, resulting in a high yield of finished products.

Intelligent Inspection: Equipped with visual or sensor inspection modules, it automatically rejects defective products, ensuring consistent quality of medical consumables.

Clean and Safe: Operates in a clean environment to avoid secondary contamination and meet medical consumable production standards.

High Compatibility: Supports stool test tubes of various specifications to meet diverse customer production needs.

Technical Features:

PLC intelligent control system with a simple user interface and adjustable parameters.

Multiple workstations operate simultaneously, ensuring both efficiency and precision.

The automatic loading system reduces manual intervention and enables stable and continuous production.

Customizable to suit different products.

Why choose an automatic fecal test tube assembly machine?

Compared to traditional manual assembly, the automatic fecal test tube assembly machine not only significantly improves production efficiency but also ensures product consistency and cleanliness, reducing human error. For medical consumables companies, it's an ideal choice for enhancing market competitiveness and transitioning to automated production.

Equipment Details:

Model Number: GST-YBG001A

Sizes: L380cm*W270cm*H170cm

Weight: 1200kg

Power: 2.5kW

Production Capacity: 2200 pieces/hour

Voltage: 220V

Customized Support: Yes