The automatic assembly machine for atomizer filters is a fully automated assembly device designed specifically for medical consumables manufacturers. It is primarily used for the precise, rapid, and

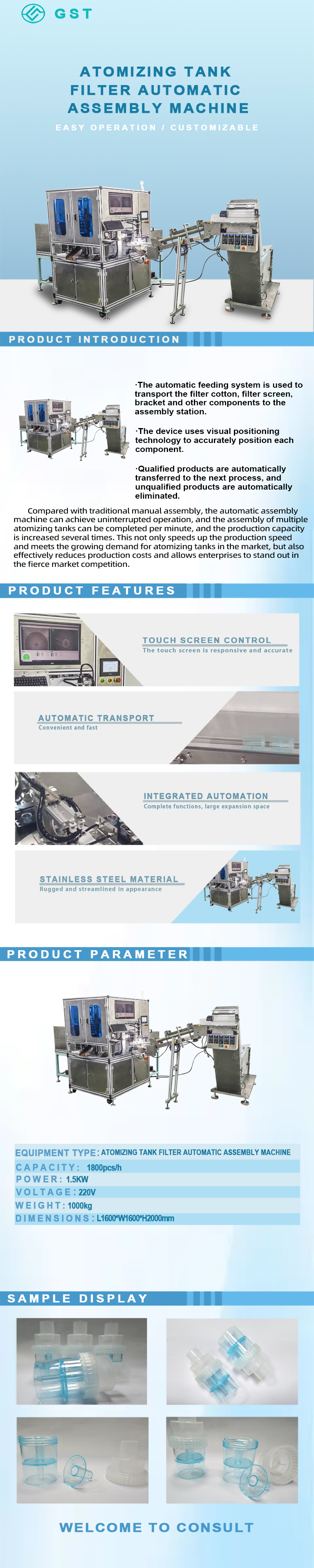

The automatic assembly machine for atomizer filters is a fully automated assembly device designed specifically for medical consumables manufacturers. It is primarily used for the precise, rapid, and clean assembly of key components, such as atomizer filters. By integrating multiple processes, including automated loading, positioning, press-fitting, inspection, and discharge, the machine achieves efficient and stable production lines, significantly improving product consistency and production capacity, and meeting the medical industry's stringent quality and cleanliness requirements.

Core Advantages:

Fully automated assembly: From automatic component loading to finished product discharge, the entire process is unmanned, reducing manual intervention and lowering costs.

High-precision control: Utilizing servo motors and an intelligent control system, each filter is assembled with the correct position, force, and precision.

Clean design: The entire machine structure and materials meet the cleanliness standards of medical consumables production, effectively preventing secondary contamination and ensuring product safety.

Intelligent inspection: Built-in vision or sensor inspection systems monitor assembly quality in real time, automatically rejecting defective products and improving yield.

Easy operation: Equipped with a PLC control and touchscreen human-machine interface, adjustable parameters enable quick switching between atomizer filters of different specifications.

Technical Features:

High-speed production: Supports 24/7 continuous operation, significantly improving production efficiency.

Modular design: Functionality can be expanded according to customer needs, including labeling, coding, and packaging modules.

Stable and durable: Components are made of high-quality materials, ensuring easy maintenance and a long service life.

Data-driven management: Automatically calculates production output and defect rates, providing data support for quality traceability and production management.

Compared to traditional manual or semi-automatic assembly methods, the automatic assembly machine for atomizer can filters not only improves production efficiency and product consistency, but also significantly reduces labor costs and human error. For medical consumables manufacturers, this is a key device that helps factories achieve intelligent manufacturing, standardization, and large-scale production.

Equipment Details:

Model Number: GST-WHG001A

Sizes: L160cm*W160cm*H200cm

Weight: 1000kg

Power: 1.5KW

Production Capacity: 1800 PCS/hour

Voltage: 220V/50Hz

Core Components: Motor, CCD System

Customized Support: Yes