The ESR Tube Automatic Assembly Machine is a highly efficient automated device developed for manufacturers of medical testing consumables, primarily used for the automated assembly, testing, and sor

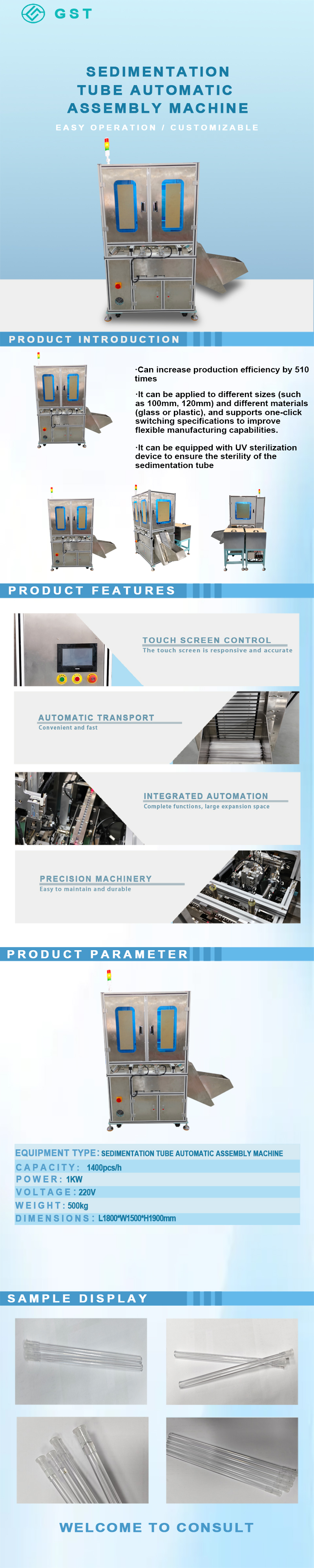

The ESR Tube Automatic Assembly Machine is a highly efficient automated device developed for manufacturers of medical testing consumables, primarily used for the automated assembly, testing, and sorting of ESR tubes. The machine integrates automatic loading, component assembly, testing and rejection, and sorting and discharge, enabling continuous, batch production in a sterile environment, significantly improving ESR tube production efficiency and end-product consistency.

Core Functions:

Fully Automatic Loading and Assembly: Automated feeding and assembly of test tubes, rubber stoppers, labels, and other components reduces manual operation.

Precise Positioning: Utilizing a servo system and photoelectric sensing technology, high-precision alignment ensures accurate assembly.

In-Line Inspection: Equipped with a visual or sensor inspection system, it automatically identifies and rejects missing, incorrectly installed, or damaged products, ensuring product quality.

Flexibility: Supports rapid switching between ESR tubes of varying specifications and capacities to meet diverse order requirements.

Intelligent Control: A PLC and touchscreen human-machine interface enable flexible parameter settings and a clear overview of operating status.

Technical Features:

Modular design facilitates maintenance and functional expansion;

Stable operation, low noise, and low energy consumption;

Seamlessly integrated with previous and subsequent processes (such as cleaning, disinfection, and packaging) to create a fully automated production line;

High-quality components and rigorous manufacturing processes extend equipment life and reduce failure rates.

Compared to traditional manual or semi-automatic assembly, the ESR tube automatic assembly machine not only significantly improves production efficiency and reduces labor costs, but also significantly enhances product quality consistency and production environment hygiene standards, helping companies meet medical device regulations and GMP requirements. It is an ideal device for consumables factories to move towards intelligent manufacturing and enhance market competitiveness.

Equipment Details:

model number: GST-XCG001A

Sizes: L180cm*W150cm*H190cm

Weight: 500kg

Power: 1KW

Production Capacity: 1,400 PCS/hour

Voltage: 220V/50Hz

Core Component: Motor

Customized Support: Yes