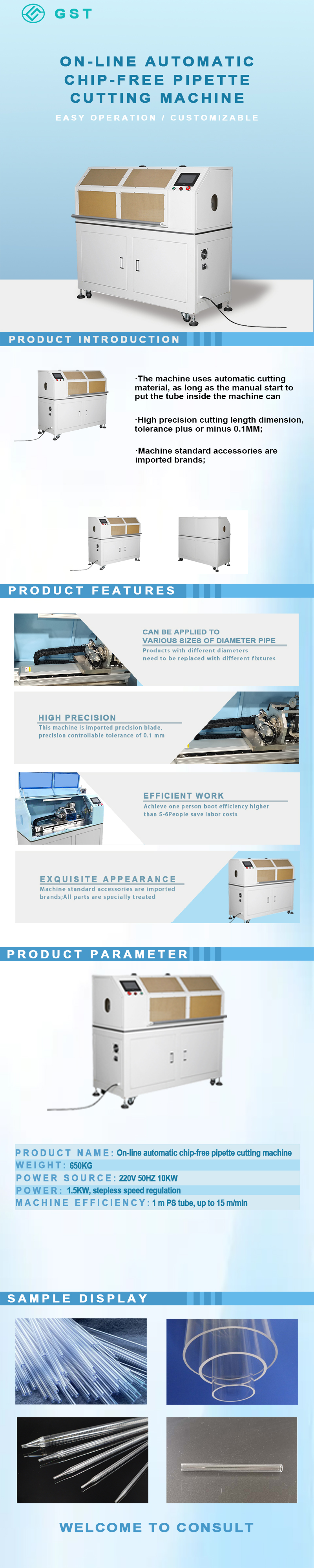

The online, chip-free plastic tube automatic cutting machine, also known as an in-line pipe cutter, is a high-efficiency CNC cutting device designed specifically for plastic tube production lines. I

The online, chip-free plastic tube automatic cutting machine, also known as an in-line pipe cutter, is a high-efficiency CNC cutting device designed specifically for plastic tube production lines. It is suitable for in-line cutting of laboratory consumables, medical tubing, and other plastic tubing products. This machine can be directly connected in parallel with extrusion, drawing, and forming processes, achieving non-stop, simultaneous cutting. This eliminates the need to remove the tube before cutting, thereby improving production efficiency. The cut is smooth, burr-free, and debris-free, eliminating the need for secondary cleaning and contamination, significantly reducing post-processing costs.

Chip-free cutting technology: Utilizing specialized cutting tools and a rotary cutting method, the cut is smooth and flat, free of burrs or plastic debris.

High-speed in-line cutting: The machine can synchronize cutting speeds with upstream production equipment for continuous operation. Typical models can support cutting speeds of several meters per minute.

High-precision control: Equipped with a servo drive, precision bearings, and an intelligent control system, the cut length error is controlled within ±0.1 mm.

Automatic discharge and rejection: After cutting, the tubes are automatically unloaded, and abnormal or miscut parts are automatically rejected, facilitating full-line automation integration.

Compatible with multiple tube specifications: Supports cutting of plastic tubes of varying diameters and wall thicknesses, simply by replacing the fixture or adjusting the parameters.

Intelligent control interface: The intuitive user interface allows users to set parameters such as cutting length, speed, and interval via a PLC or touchscreen interface, while also monitoring operating status in real time.

Highly durable design: Key components are constructed of high-quality materials and feature wear-resistant treatments, ensuring long tool life and low maintenance costs.

This in-line, chip-free automatic tube cutting machine is particularly suitable for applications requiring high cleanliness and cutting quality, such as medical tubing, laboratory consumables, in vitro diagnostic tubing, pipettes, and reagent tubes. By seamlessly integrating the cutting process into the production line, it significantly increases production throughput, reduces secondary processing, and ensures the precision and cleanliness of the end product.

Technical Parameters:

Equipment Model: GST-YYG100A

Pipette capacity: 1-100ml

Cutting efficiency: 1 meter tube, can reach 15 meters / min

Cutting precision: tolerance ± 0.1mm

sizes: 2600*600*1700mm

production capacities: 15m/min for 1 meter pipe

power (output): 1.5KW

Customized Support: Yes