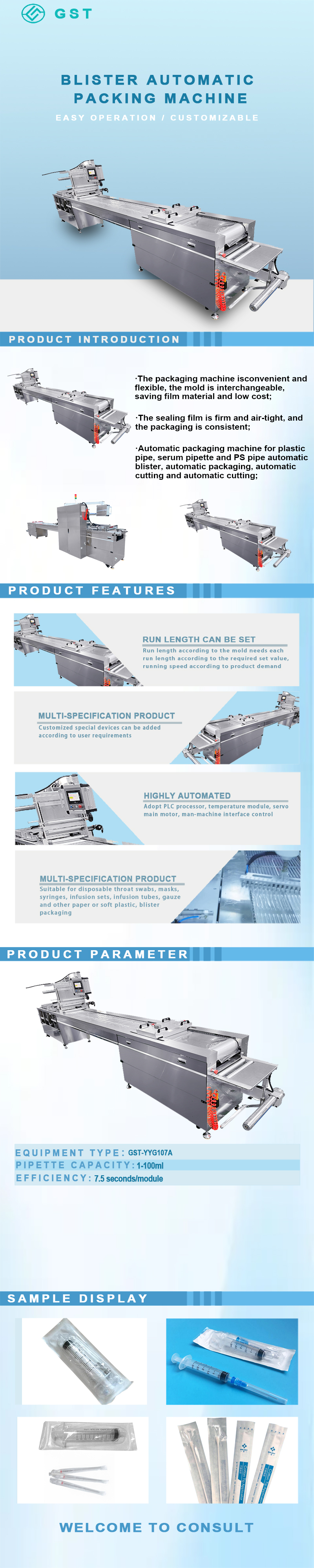

This automatic blister packaging machine is specifically designed for pipettes, plastic tubing, and PS tubing in the laboratory consumables sector. It integrates blister forming, automatic packaging

This automatic blister packaging machine is specifically designed for pipettes, plastic tubing, and PS tubing in the laboratory consumables sector. It integrates blister forming, automatic packaging, slitting, and unloading. This highly automated and flexible machine is suitable for production environments requiring high sealing, cleanliness, and packaging consistency.

Blister Forming: First, the plastic sheet (film) is heated and softened. Then, the blister is formed through a mold to create a groove/cavity to accommodate the pipette. This process requires strict control of temperature, molding pressure, and film tension to ensure consistent molding and dimensional accuracy.

Automatic Packaging and Filling: After the sheet is formed, the pipette is aligned and placed into the blister slot. The machine automatically and precisely loads the pipette. The filling process is coordinated by a feeding mechanism and a positioning device.

Slitting and Sealing: After the blister is formed and the product is loaded, the film or paper material on the other side is aligned and heat-sealed. The finished packaging units are then cut vertically and horizontally. Waste is removed and recycled.

Automatic unloading and conveying: Cut finished products are automatically unloaded by a robot or conveyor and transported to subsequent packaging, labeling, or boxing stations. Seamless integration with the entire production line ensures seamless operation.

Interchangeable molds for flexible packaging: The mold design features a universal structure, allowing for quick replacement to accommodate blister packaging for pipettes or plastic tubing of varying sizes.

Film material savings and low costs: The machine utilizes an optimized blister process and lamination strategy to maximize film utilization and minimize waste, thereby reducing packaging consumables costs.

Secure and airtight film sealing: The sealing process is temperature- and pressure-controlled, ensuring high-quality sealing and a reliable, airtight seal.

Both automation and cleanliness are emphasized: The machine utilizes a modular design for a compact structure; precise motion paths; and easy integration with upstream equipment (such as loading, testing, and labeling). The machine's surface material is easy to clean, meeting cleanroom requirements.

Widely applicable: The machine accommodates pipettes with capacities ranging from 1 mL to 100 mL.

Improved Production Efficiency: Replacing the traditional manual blister packaging process with an automated system significantly improves packaging cycle time and efficiency.

Reduced Labor and Error Costs: Reducing manual operations reduces human error and defective product rates.

Guaranteed Quality Consistency: Each product is securely sealed and highly consistent; suitable for packaging high-standard laboratory consumables.

Strong Line Integration: Seamlessly integrates with printing, leak detection, cartoning, labeling, and automatic feeding equipment to create a complete automated packaging line.

Technical parameters:

Equipment Model: GST-YYG107A

Pipette capacity: 1-100ml

sizes: L6000*W900*H1800mm

production capacities: 7.5 seconds/module

power (output): 380VAC

Customized Support: Yes