The Atomizer Canister Filter Automatic Assembly Machine is a highly efficient automated device designed for medical and industrial atomizer device manufacturers, specifically designed for the precis

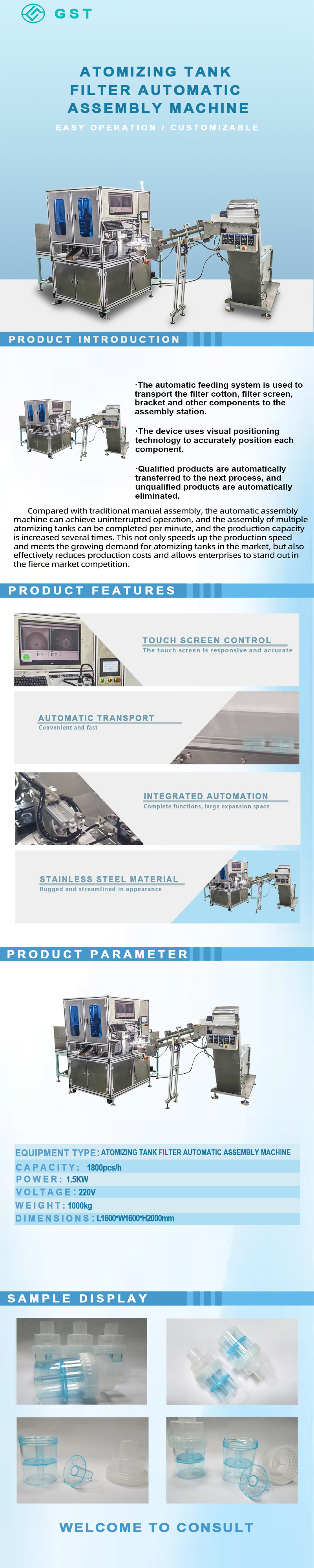

The Atomizer Canister Filter Automatic Assembly Machine is a highly efficient automated device designed for medical and industrial atomizer device manufacturers, specifically designed for the precise assembly and seal testing of atomizer canister filter assemblies. This device integrates automated loading, oriented alignment, assembly, pressing, and in-line testing of raw materials (such as filter membranes, filter housings, plugs, and seals), effectively reducing manual errors and improving production line stability and yield.

Automatic Loading and Sorting: Filter housings, filter membranes, and seals are automatically sorted and conveyed using a vibrating plate or hopper, providing a stable and continuous supply of materials for subsequent assembly processes.

Precise Positioning and Assembly: A mechanical fixture coupled with vision positioning or photoelectric detection technology ensures accurate alignment and insertion of the filter membrane and housing. Initial assembly is completed by pressing, welding, or bonding filter elements, seals, and other components.

Pressing/Fixing Logic: A motor-driven or pneumatic mechanism is used to uniformly press components together, combining heat fusion, adhesive bonding, or ultrasonic welding to ensure a secure seal.

Online Leakage/Leakage Testing: After assembly, the device performs an air-tight or liquid-tight test on each filter element. Leaks are identified using differential pressure, pressure fluctuations, or flow rate detection, and defective products are automatically rejected.

Intelligent Control System: The device utilizes a PLC + HMI control platform, allowing flexible configuration of assembly parameters, testing standards, alarm thresholds, and more. It also supports program saving, model switching, and real-time monitoring.

Modular Design: The device's various functional modules (loading, assembly, testing, and rejection) utilize a modular design, allowing for quick fixture replacement and parameter adjustment based on filter specifications, facilitating maintenance and upgrades.

High Efficiency and High Consistency: Automated operations replace manual labor, resulting in fast and stable assembly and significantly increased production capacity.

Quality Guarantee: Introducing online inspection and rejection mechanisms ensures only qualified components advance to the next step.

Strong Customization: Automated assembly supports diverse filter specifications, materials, and structures, allowing for flexible equipment commissioning.

Durable and Easy-to-Clean Structure: Contact parts are constructed of corrosion-resistant materials, and the compact design facilitates cleaning and maintenance.

Full-Line Integration: Seamless integration with filling, labeling, packaging, and logistics equipment allows for a complete automated production line.

Equipment Details:

Model Number: GST-WHG001A

Sizes: L160cm*W160cm*H200cm

Weight: 1000kg

Power: 1.5KW

Production Capacity: 1800 PCS/hour

Voltage: 220V/50Hz

Core Components: Motor, CCD System

Customized Support: Yes