This semi-automatic filling equipment is designed for high-viscosity pastes, creams, pasty liquids, and gels, and is suitable for quantitative filling in the food, cosmetics, pharmaceutical, daily c

This semi-automatic filling equipment is designed for high-viscosity pastes, creams, pasty liquids, and gels, and is suitable for quantitative filling in the food, cosmetics, pharmaceutical, daily chemical, and chemical industries.

Core Functions and Structure:

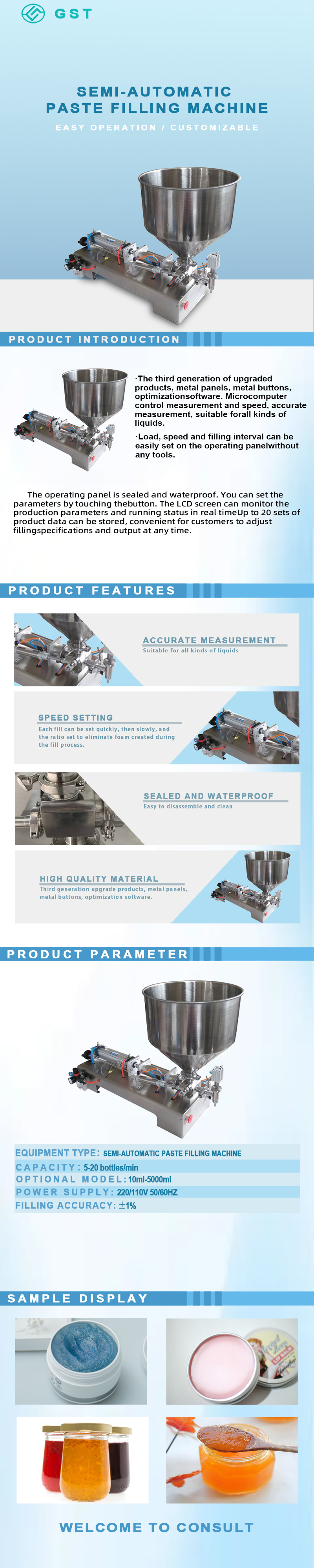

The equipment utilizes a pneumatic/servo-driven quantitative filling system specifically designed for high-viscosity materials such as pastes, creams, and gels.

The machine is equipped with a large-capacity material hopper/tank. The hopper and contact parts are constructed of 304 or 316L stainless steel, meeting food-grade and pharmaceutical-grade hygiene standards and allowing for easy disassembly and cleaning.

Filling volumes can be customized, ranging from 10 ml to 5000 ml, accommodating small-batch pilot runs to medium-scale production.

Filling accuracy is within ±1%, with a filling speed of approximately 5-20 bottles per minute (depending on the material and specifications).

The simple user interface, available with either a foot switch or manual touch control, makes it suitable for semi-automatic production lines and reduces training costs.

The modular design allows for quick replacement or upgrade of filling heads, hoppers, and conveyor mechanisms based on material properties (such as viscosity and flowability).

The equipment's compact structure makes it ideal for space-constrained workshops that require flexible switching between different production lines.

Applicable Industries and Scenarios:

Cosmetics: Filling high-viscosity materials such as creams, gels, massage creams, hand creams, and hair dyes.

Pharmaceutical/Daily Chemicals: Filling ointments, disinfectant gels, toothpastes, and antigen reagent pastes.

Food: Filling high-viscosity products requiring precise metered filling, such as sauces, honey pastes, jams, and peanut butter.

Chemicals: Filling adhesives, lubricating pastes, silicone greases, and sealants.

Due to its wide range of applications, flexible structure, and relatively low investment costs, this system is particularly suitable for small and medium-sized businesses or manufacturers seeking to transition from manual to semi-automated production.

Technical parameters:

Model Number: GST-SWYP003A

Sizes: 1600*300*1000mm

Optional models: 10ml -5000ml ;

Power supply: 220/110V 50/60HZ.

Air pressure: 0.4-0.6MPa.

Filling speed: 5-20 bottles/minute (the machine power for the gas source, can meet the large and small enterprises to use);.

Filling precision: ≤±1%.

Customized Support: Yes