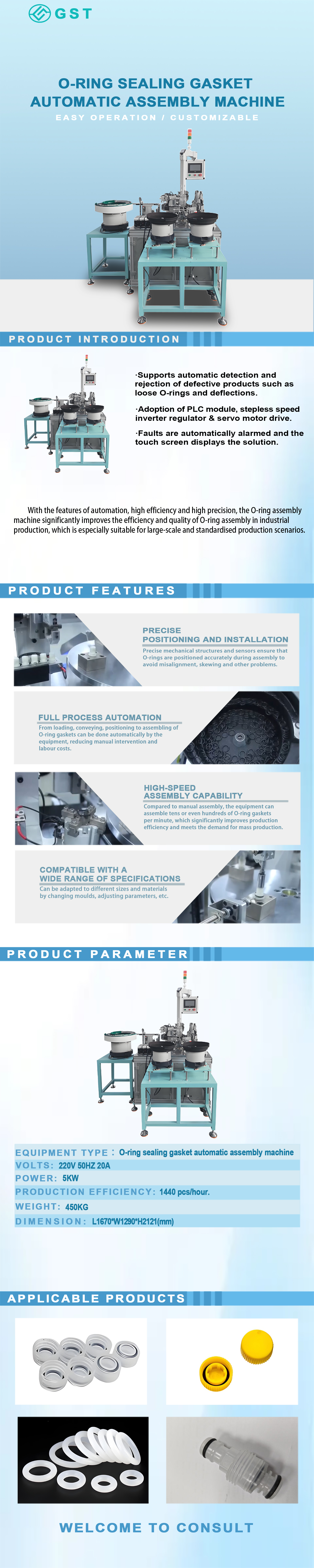

The O-ring automatic assembly machine is a highly efficient automated device designed specifically for O-ring gasket assembly. It integrates automatic loading, gasket positioning, press-fit assembly

The O-ring automatic assembly machine is a highly efficient automated device designed specifically for O-ring gasket assembly. It integrates automatic loading, gasket positioning, press-fit assembly, in-line inspection, and reject/ejection. It is suitable for automated O-ring installation processes in industries such as hardware, mechanical seals, hydraulic components, cylinder components, and molds, significantly improving production efficiency, assembly quality, and consistency.

Equipped with a vibrating plate or feed track, the machine automatically sorts and aligns O-rings and accessories, eliminating manual picking and positioning steps and improving production cycle times.

Precise press-fit positioning mechanism: Utilizing a hybrid electric/pneumatic drive or servo-controlled press head, combined with a positioning fixture, precisely controls the press-fit depth and assembly angle of the O-ring, ensuring a secure, correct, and distorted assembly.

In-line inspection and rejection: Built-in sensors or a visual inspection system detect missing, skewed, or improperly pressed gaskets. Automatic rejection of defective assembly parts effectively improves yield rate and factory quality.

Modular Changeover Structure: The machine's modular design allows for quick replacement of fixtures and molds to accommodate O-rings and accessories of varying sizes and specifications, meeting the flexible production requirements of high-variety, small-batch production.

Intelligent Control System: Utilizing a PLC and touchscreen human-machine interface, the system offers convenient and intuitive operation. It allows for preset assembly parameters, press force, cycle speed, and production statistics for different products, supporting fault alarms, data logging, and traceability.

Sturdy and Easy-Maintenance Structure: The machine body is constructed of aluminum alloy or a stainless steel frame, and the transmission system is enclosed and dust-proof, making it easy to maintain and suitable for continuous operation.

Technical parameters:

Model Number: GST-WJ012A

Sizes: L1670*W1290*H2121(mm)

Production Capacities: 1440pcs/h

Power (Output): 220V/50HZ 20A 5KW

Customized Support: Yes