Release Date:2024-05-27 13:47:23 Popularity:

In the process of global manufacturing transforming to intelligence and automation, fully automatic assembly lines, as an advanced production model, are playing an important role in all walks of life. The fully automatic assembly line integrates a variety of high-tech equipment and systems to achieve full automation and intelligence in the production process. It not only greatly improves production efficiency and product quality, but also promotes innovation and development in the manufacturing industry. This article will explore the main features, advantages and applications of fully automated assembly lines in different fields.

Characteristics of a fully automatic assembly line. A fully automatic assembly line is a highly comprehensive production system. Its core features include the following aspects:

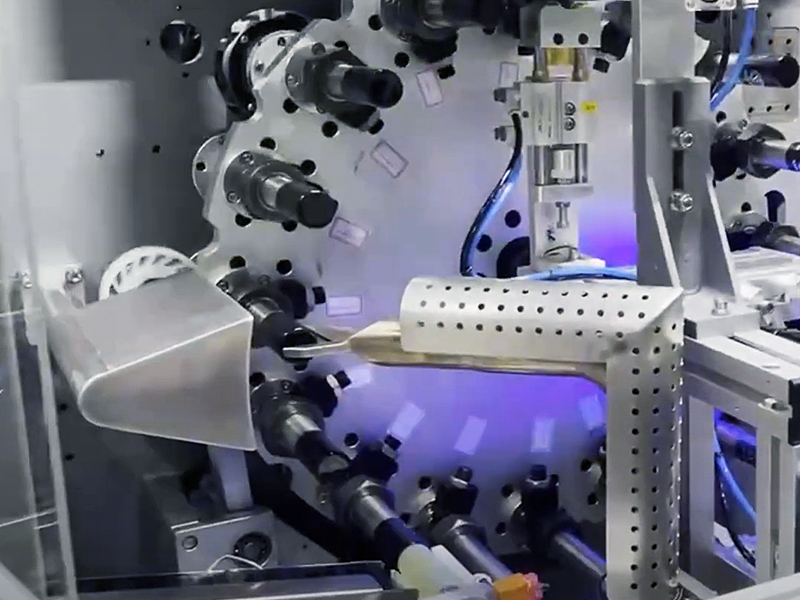

1. High degree of automation: The fully automatic assembly production line realizes full automation from raw material processing, parts assembly to finished product inspection and packaging through automated equipment and control systems, greatly reducing manual intervention.

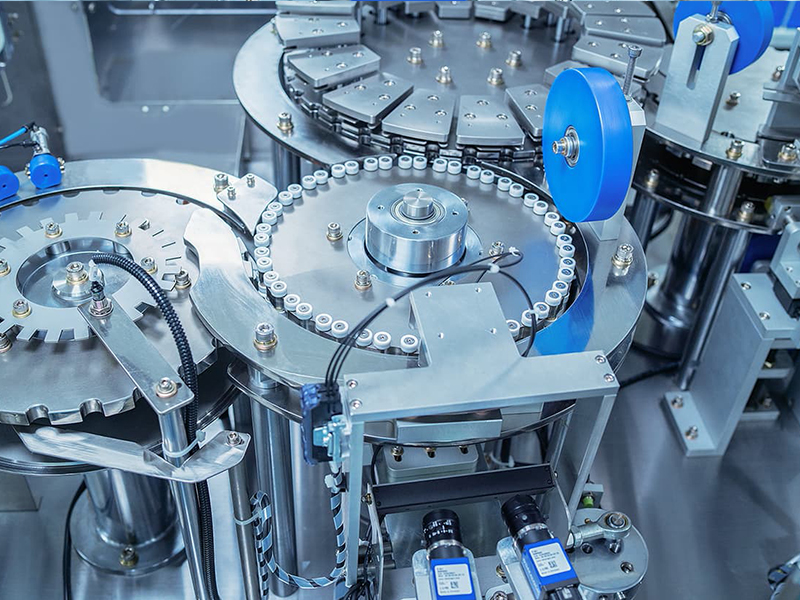

2. Intelligent control: The production line is usually equipped with advanced PLC (programmable logic controller), robots, sensors and MES (manufacturing execution system), etc., which can monitor and optimize the production process in real time and improve the accuracy and efficiency of production.

3. Flexibility and scalability: The fully automatic assembly production line has a high degree of flexibility and can be quickly adjusted and configured according to the needs of different products and processes, adapting to multi-variety, small-batch production models.

4. Data-driven: The production line integrates a large number of data collection and analysis systems. Through real-time monitoring and analysis of production data, predictive maintenance and production optimization can be achieved, and equipment utilization and production efficiency can be improved.

5. Modular design: A fully automatic assembly production line with modular design can add, remove, and replace modules according to production needs, making it easier for enterprises to adjust and upgrade the production line.

Advantages of fully automatic assembly production line:

1. Improve production efficiency: The fully automatic assembly production line significantly improves production efficiency through continuous, high-speed automated production operations. It is especially suitable for mass production and can meet the market's demand for rapid product delivery.

2. Ensure product quality: The fully automatic assembly production line ensures the accuracy and consistency of each production link through precise control systems and automated testing equipment, thereby improving product quality and reducing the defective rate.

3. Reduce production costs: Automated production lines reduce reliance on labor and reduce labor costs. At the same time, the efficient use of automated equipment and reduced material waste also reduce production costs.

4. Enhance production safety: The fully automatic assembly production line replaces manual operations with mechanical equipment, reducing the opportunities for workers to directly come into contact with production equipment, thus reducing safety risks in the production process.

5. Achieve flexible production: Fully automatic assembly production lines can quickly respond to market changes, adapt to the production needs of different products by flexibly adjusting production processes and parameters, and enhance the market competitiveness of enterprises.

Application fields of fully automatic assembly lines. Fully automatic assembly lines have been widely used in many industries. Their high efficiency, accuracy and flexibility make them particularly prominent in the following fields:

1. Electronic product manufacturing: In the field of electronic product manufacturing, fully automatic assembly production lines are used for the assembly and testing of smartphones, computers, household appliances and other products. Through highly sophisticated automation equipment, the assembly efficiency and quality of products are improved.

2. Automobile manufacturing: The automobile manufacturing industry is an important application field for fully automatic assembly production lines. Automated production lines are used for the assembly and testing of key components such as engines, gearboxes, and bodywork, improving production efficiency and product consistency, and meeting the needs of mass production of automobiles.

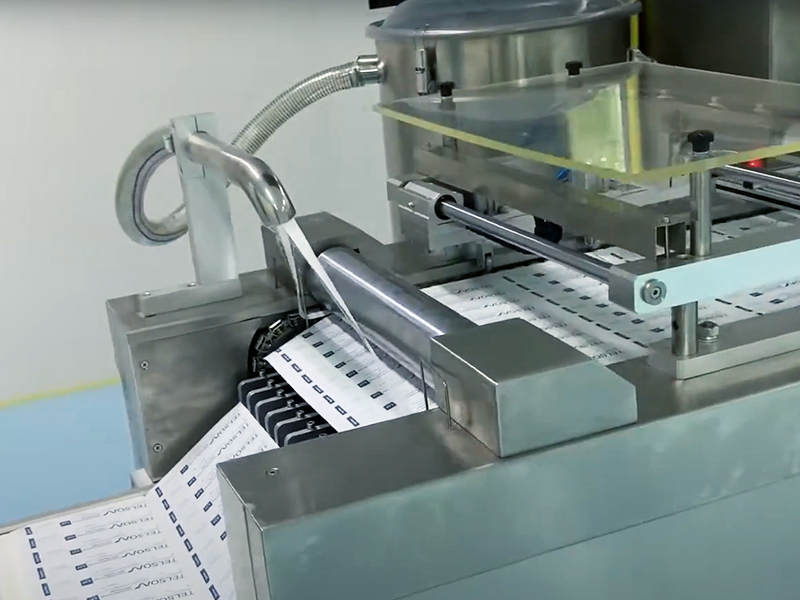

3. Medicine and medical equipment: In the medicine and medical equipment industry, fully automatic assembly lines are used for the production of medicines, syringes, medical equipment and other products. Through strict automation control and sterile environment, the safety and quality of the products are ensured.

4. Home and furniture manufacturing: In the field of home and furniture manufacturing, fully automatic assembly production lines are used for the automated assembly of furniture parts. Through efficient production processes, the production efficiency and quality of products are improved, and production costs are reduced.

5. Daily chemical products: In the field of daily chemical products, fully automatic assembly production lines are used for filling, packaging and packaging of detergents, cosmetics, skin care products and other products, which improves the production speed and consistency of product appearance, and enhances the brand image. .

As the core driving force of intelligent manufacturing, the fully automatic assembly line has significantly improved the production efficiency and product quality of various industries with its high degree of automation, intelligent control and flexible scalability. In the future development, with the continuous advancement of technology and changes in market demand, fully automatic assembly production lines will continue to play an important role in helping the manufacturing industry achieve more intelligent, flexible and efficient development, and promote the global manufacturing industry towards a more intelligent, flexible and efficient development. new heights.