Release Date:2024-06-07 15:20:13 Popularity:

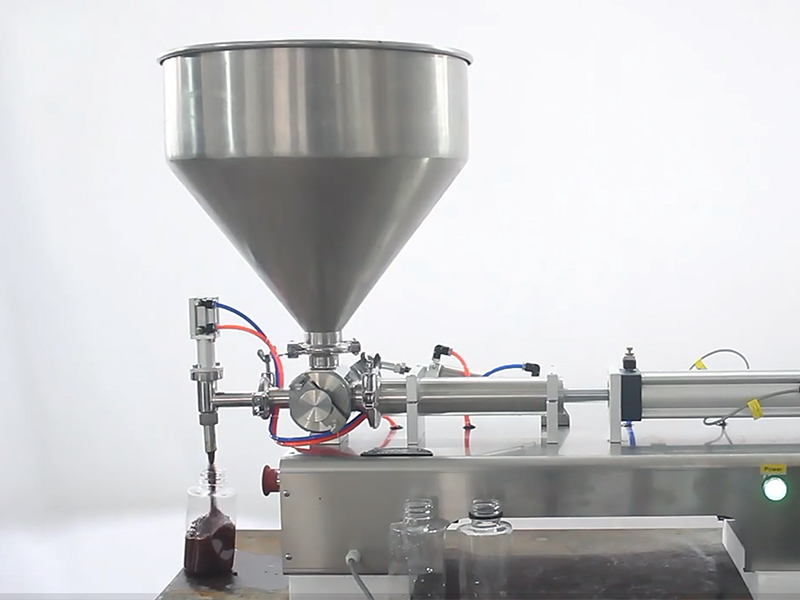

In today's manufacturing industry, the production and packaging of paste products has become an important task. In order to meet market demand and improve production efficiency, paste filling machines have become an indispensable key equipment. This article will explore in depth the significance, technical characteristics and impact of paste filling machines on production efficiency.

The significance of paste filling machines

The emergence of paste filling machines marks a major shift in production methods. Compared with traditional manual filling, paste filling machines have higher precision, speed and stability. It can realize automated production processes, thereby improving production efficiency, reducing costs, and ensuring the stability of product quality. In an increasingly competitive market environment, paste filling machines have won valuable competitive advantages for enterprises.

Technical features of paste filling machines

1. Accurate filling control: The paste filling machine is equipped with advanced metering systems and flow control technology, which can accurately control the amount of each filling to ensure product consistency.

2. Efficient production speed: The paste filling machine can perform filling operations continuously at a higher speed, greatly improving production efficiency and saving time and labor costs.

3. Applicable to a variety of paste products: The paste filling machine has strong versatility and adaptability, and can be applied to various types and viscosities of paste products, such as cosmetics, ointments, foods, etc.

4. Automated operation process: The paste filling machine adopts an advanced automatic control system to achieve full-process automated operation, reduce human intervention, and improve the stability and reliability of the production line.

5. Safe production environment: The paste filling machine has multiple safety protection measures to ensure the safety of operators and equipment and reduce safety risks in the production process.

The impact of the paste filling machine on production efficiency, the application of the paste filling machine has a significant improvement in production efficiency:

1. Improved production speed: The paste filling machine can continuously perform filling operations at a higher speed, greatly speeding up the production process and achieving fast and efficient production.

2. Reduced production costs: Compared with manual filling, the paste filling machine can reduce labor costs and reduce scrap rates, thereby reducing production costs and improving the competitiveness of the enterprise.

3. Improved product quality: The precise control system of the paste filling machine can ensure that the filling volume of the product remains consistent every time, improving the quality stability and consistency of the product.

4. Saved human resources: The automated operation of the paste filling machine reduces the demand for human resources, saves labor costs, and also reduces the labor intensity on the production line.

5. Enhanced the stability of the production line: The automated operation process and safety protection measures of the paste filling machine improve the stability of the production line, reduce equipment failures and downtime, and further improve production efficiency.

As an intelligent assistant for modern production, the paste filling machine plays an important role in improving production efficiency, reducing costs, and ensuring product quality. With the continuous advancement of science and technology and the development of the manufacturing industry, the paste filling machine will be further improved and innovated to provide more reliable and efficient solutions for the production of various industries and promote enterprises to move towards intelligent manufacturing.