Release Date:2024-07-06 14:20:38 Popularity:

With the advancement of science and technology and changes in market demand, small automatic quantitative packaging machines have been widely used in all walks of life. It not only improves packaging efficiency, but also ensures the quality and consistency of products. This article will explore the working principle, main features, application advantages and importance of small automatic quantitative packaging machines in modern production.

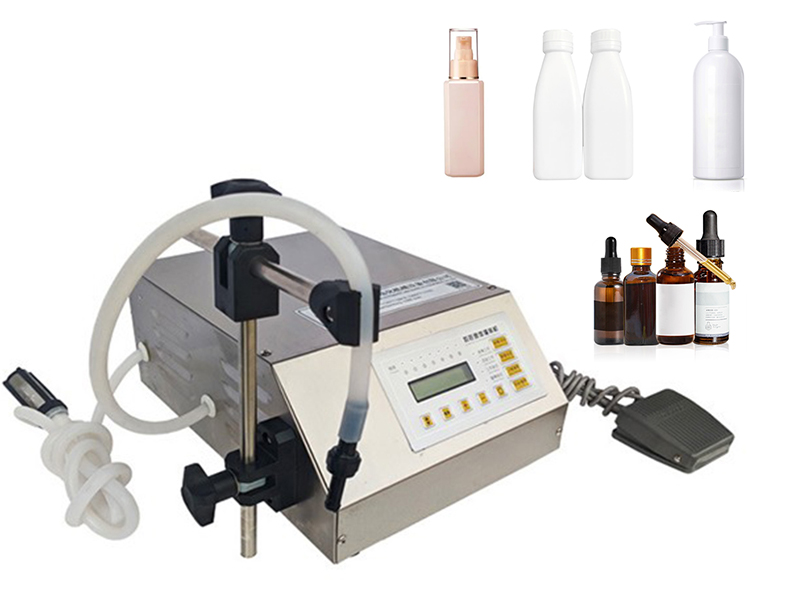

Small automatic quantitative packaging machine is a device that integrates weighing, metering, filling, sealing and other functions. Its working process mainly includes the following steps:

1. Feeding system: The material to be packaged is transported to the weighing bucket through an automatic feeding device. The feeding system can be adjusted according to different material characteristics to ensure the continuity and stability of feeding.

2. Weighing system: The weighing bucket accurately weighs the material through a high-precision weighing sensor to ensure that the weight of each package of product meets the preset standard. The weighing system can be adjusted according to different specifications of the product to adapt to a variety of weight ranges.

3. Filling system: After weighing, the material automatically enters the packaging bag through the filling device. The filling system is reasonably designed to ensure that the material is not contaminated or lost during the filling process.

4. Sealing system: After filling, the packaging bag is sealed by the sealing device. The sealing system can select the appropriate sealing method according to different packaging materials, such as heat sealing, pressure sealing, etc., to ensure the sealing and leakproofness of the packaging bag.

5. Output system: The sealed packaging bag is transported to the designated location through the conveyor belt to complete the entire packaging process.

Main features of small automatic quantitative packaging machine

1. High efficiency: The small automatic quantitative packaging machine significantly improves the packaging efficiency through automated operation. Compared with the traditional manual packaging method, automated equipment can complete a large number of packaging tasks in a short time to meet the needs of large-scale production.

2. Accuracy: High-precision weighing sensors and advanced control systems ensure that the weight of each package of products is accurate and consistent, avoiding quality problems caused by inaccurate packaging quantity.

3. Stability: The automated equipment operates stably and reliably, can maintain efficient working conditions for a long time, and reduces the risk of equipment failure and production interruption.

4. Diversity: The small automatic quantitative packaging machine is suitable for the packaging needs of a variety of materials, including granules, powders, liquids, etc. Through different feeding and filling devices, it can meet diverse production requirements.

5. Intelligence: The intelligent control system and human-machine interface are easy to operate, and can be quickly adjusted and parameterized according to different packaging requirements to achieve diversified packaging.

6. Energy saving and environmental protection: The design of modern small automatic quantitative packaging machines focuses on energy saving and environmental protection, reducing energy consumption and material waste, and meeting the requirements of sustainable development.

Application advantages of small automatic quantitative packaging machines

1. Improve production efficiency: Small automatic quantitative packaging machines significantly improve packaging efficiency through automated operation. Automated equipment not only speeds up packaging, but also reduces errors and time waste in manual operation, improving the overall efficiency of the production line.

2. Improve product quality: High-precision weighing and filling systems ensure the consistency of weight and quality of each package of products. Automated packaging reduces quality fluctuations caused by manual operation, improves product consistency and market competitiveness.

3. Reduce production costs: Although the initial investment of small automatic quantitative packaging machines is large, their efficient production capacity and low operating costs significantly reduce the overall production costs. Automated equipment reduces dependence on manual labor, reduces labor costs and management costs. In addition, precise packaging control systems reduce material waste and improve resource utilization.

4. Improve production safety: Automated packaging equipment reduces the chances of workers being exposed to harmful substances and dangerous environments by replacing manual work to complete some highly dangerous tasks, thereby improving the safety of the production process. The intelligent system can also monitor the production status in real time, and promptly discover and deal with potential safety hazards.

5. Enhance market competitiveness: Small automatic quantitative packaging machines can quickly adjust production according to market demand, improving the market response speed of enterprises. Efficient production capacity and high-quality product quality enable enterprises to occupy a favorable position in the fierce market competition.

The importance of small automatic quantitative packaging machines in modern production

With the continuous changes in market demand and the improvement of consumer requirements for product quality, the importance of small automatic quantitative packaging machines in modern production has become increasingly prominent. It not only improves production efficiency and product quality, but also reduces production costs and improves production safety. It has been widely used in many industries such as food, medicine, chemical industry, agricultural products, etc., and has become an important means for modern production enterprises to enhance their competitiveness.

1. Food industry: In food packaging, small automatic quantitative packaging machines are widely used in the packaging of candies, nuts, coffee beans, grains and other products, which improves packaging speed and quality and ensures the hygiene and safety of food.

2. Pharmaceutical industry: In pharmaceutical packaging, small automatic quantitative packaging machines are used for precise packaging of medicines, health products and other products, ensuring the accurate dosage of each package of products, and improving the quality and safety of medicines.

3. Chemical industry: In chemical packaging, small automatic quantitative packaging machines are used for the packaging of chemical products such as powders, granules, and liquids, ensuring the packaging quality and safety of products, and reducing material waste and pollution.

4. Agricultural products industry: In agricultural product packaging, small automatic quantitative packaging machines are used for the packaging of seeds, fertilizers, feed and other products, improving packaging efficiency and quality, and ensuring the quality and safety of agricultural products.

With its high efficiency, precision, stability, intelligence and diversity, small automatic quantitative packaging machines are leading the packaging industry towards automation and intelligence. It has significant advantages in improving production efficiency, improving product quality, reducing production costs and enhancing market competitiveness, and has become an important means for modern production enterprises to enhance their competitiveness. With the continuous advancement of science and technology, small automatic quantitative packaging machines will continue to develop and bring more innovations and opportunities to the packaging industry. In the future, small automatic quantitative packaging machines will continue to play their important role and promote the packaging industry to move towards a more efficient, intelligent and sustainable development direction.