Release Date:2025-07-07 15:06:45 Popularity:

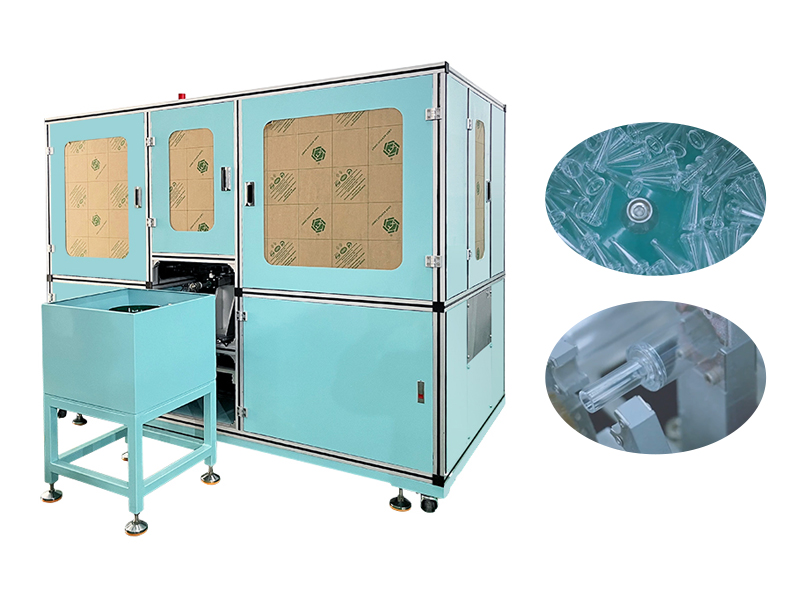

In many precision fields such as modern medical testing, biological experiments, and chemical research, pipettes, as one of the basic experimental consumables, are widely used in the precise distribution and operation of trace liquids. With the acceleration of laboratory automation and consumables standardization, higher requirements are placed on the sealing, consistency, and cleanliness of pipettes. In the production process of pipettes, especially the connection between the pipette body and the nozzle, and the pipette body and the filter element seal, it has become a key process link affecting product quality. Traditional hot melt, adhesive and other methods have problems such as low efficiency, high pollution, and insufficient strength. Therefore, pipette ultrasonic welding machines came into being and became a new solution for achieving high-quality, pollution-free, and high-efficiency welding.

1. The criticality of pipette welding process

The structure of the pipette usually includes the pipette body, the tip interface and the filter element packaging position. These parts must be sealed and connected in a firm and pollution-free way to ensure:

Good airtightness to prevent liquid or gas leakage; the inside of the pipette is clean and free of impurities, suitable for sterile experiments;

The welding part is free of burrs and deformation to ensure smooth operation;

High batch consistency to meet large-scale industrial production.

Traditional adhesives or hot melt methods often have defects in the above aspects, while ultrasonic welding technology provides a more superior performance guarantee.

2. Working principle of pipette ultrasonic welding machine

Ultrasonic welding is a technology that uses high-frequency mechanical vibration energy to quickly melt the plastic contact surface to achieve a firm connection. The pipette ultrasonic welding machine completes the welding process through the following steps:

High-frequency electrical energy conversion: The ultrasonic generator inside the equipment converts electrical energy into 20kHz~40kHz high-frequency electrical vibration.

Energy transfer: The vibration is transmitted to the welding part of the pipette through the transducer and the welding head.

Frictional heat fusion: high-frequency vibration causes intense friction in the plastic joint, which melts instantly, and the welding is completed after cooling after melting.

Pressure molding: the welding head is pressed together under appropriate pressure to make the welding firm and uniform.

This welding method does not require adhesives, nails or other additional materials. The weld position is neat, firm and free of external pollution. It is especially suitable for the production of pipettes with extremely high requirements for cleanliness and precision.

3. Equipment composition and technical features

A typical pipette ultrasonic welding machine consists of the following parts:

Ultrasonic generator and transducer system: core energy supply device to ensure stable amplitude and strong energy output.

Welding head and customized mold: customized according to different types of pipettes to achieve precise matching and efficient welding.

Pressure and displacement control system: constant pressure is applied through pneumatic or servo drive to ensure weld consistency.

Intelligent operation interface (HMI): touch screen control panel, supporting welding parameter setting, monitoring, data recording and alarm.

Automatic loading and unloading system (optional): adapt to automatic assembly line to improve the overall production line efficiency.

4. the advantages of ultrasonic welding machine for pipettes

Pollution-free and clean welding: no glue or heating elements are required to avoid chemical pollution and meet the high cleanliness requirements of medical and biological experiments.

Firm welding and no leakage: high weld strength and tight welding position to prevent problems such as liquid leakage and liquid dripping.

High efficiency and fast beat: a single welding cycle is usually between 0.5 and 2 seconds, suitable for continuous and batch production.

Strong controllability and easy operation: key parameters can be digitally set and stored to meet the welding requirements of different materials and structures.

Save materials and energy consumption: no additional consumables are required, the equipment has low operating power, which is in line with the trend of green manufacturing.

Compatible with pipettes of multiple specifications: quick mold replacement, suitable for pipettes of different lengths, diameters and structures.

With the increasing demand for precision, high quality and clean manufacturing of laboratory consumables, the pipette ultrasonic welding machine undoubtedly provides a more efficient, stable and industry-standard welding solution for manufacturing companies. It not only optimizes product performance and process flow, but also lays a solid foundation for companies to build an automated, intelligent and high-standard production system. With the continuous innovation of welding technology, the future production of pipettes will be more intelligent, efficient and environmentally friendly.