Release Date:2025-07-08 14:01:12 Popularity:

In high-precision operations such as biomedicine, laboratory research, and in vitro diagnosis, pipettes, as a common and basic experimental consumables, have extremely high requirements for their scale accuracy and appearance clarity. The printing of scale lines and logos not only determines the accuracy during use, but also affects the aesthetics and brand recognition of the product. Traditional monochrome printing methods can no longer meet the needs of diversification and branding, and the pipette two-color screen printer, as an efficient and accurate printing equipment, is playing an increasingly critical role in the field of experimental consumables manufacturing with its advantages in efficiency, accuracy and color expression.

1. The importance of pipette printing

The printing of pipette scale lines is not only a visual reference, but also a key basis for measuring liquids in experiments. High-quality printing must have the following characteristics:

Clear scale lines and accurate spacing ensure accurate measurement;

Strong ink adhesion, not easy to fall off, and guaranteed service life;

No blur, no offset, no ghosting, enhancing the professionalism of the product;

Meet medical standards and no harmful substances volatilize.

As major consumables brands attach importance to product personalization and brand identity, traditional monochrome printing faces technical and visual bottlenecks. At this time, two-color screen printing technology has become the mainstream upgrade direction with its stronger visual expression ability and high-efficiency process advantages.

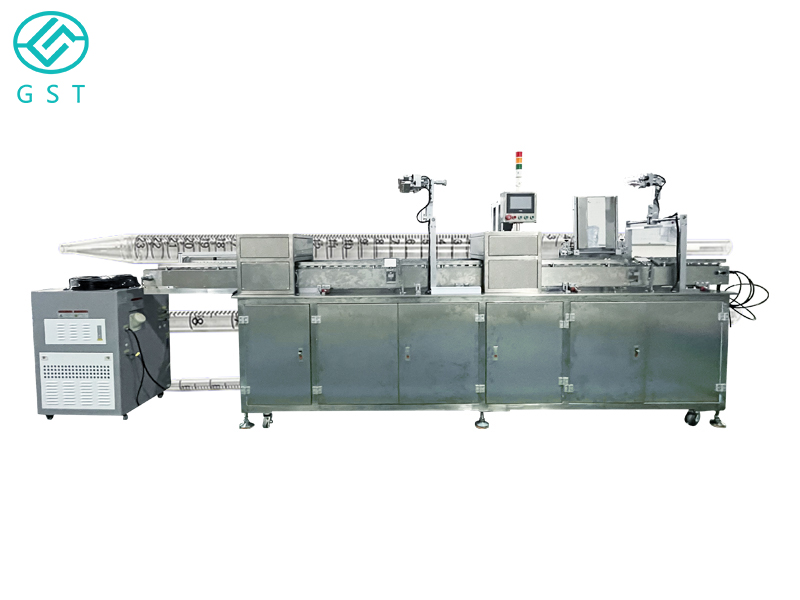

2. Equipment structure and principle of pipette two-color screen printer

The pipette two-color screen printer is an automated equipment for simultaneous two-color printing on plastic tubes. It is suitable for scale and pattern printing of various tubular consumables such as pipettes, serum tubes, and burettes. Its main components include:

Automatic feeding system: accurately deliver unprinted pipettes to the printing position through a vibration plate or conveyor belt to reduce manual intervention.

Positioning and clamping mechanism: The precision clamp fixes the pipette to ensure that it does not deviate or slide during rotation and printing.

Two-color printing system: equipped with two independent screen printing heads and ink systems, which respectively complete the printing of the main scale line and auxiliary logo or brand logo, and support independent control of different color inks.

Servo drive system: controls the precision of the rotation of the print head and the tube body to ensure accurate alignment of the printed content, and the repeated positioning error is less than ±0.1mm.

UV curing system or hot air drying module: real-time curing of ink, improving adhesion and wear resistance, and improving production efficiency.

Intelligent control and human-machine interface (HMI): the operator can set parameters such as printing speed, printing position, color sequence, drying time, etc. through the touch screen, and monitor production data.

3. Technical advantages of two-color screen printing

Improve product recognition and aesthetics: two-color printing can distinguish the scale lines from the logo, text, batch information and other contents, making the vision clearer and the brand more prominent.

Complete two-color printing at one time, high efficiency: avoid repeated processes, improve the continuity of the production line, and the daily output can reach tens of thousands of pieces to meet the needs of batch orders.

Precise printing without offset: with the servo positioning system and high-precision screen, the overlap and spacing between the two colors are kept consistent, and the scale lines and auxiliary patterns are accurately aligned.

Strong compatibility, adaptable to multiple specifications of products: by quickly changing fixtures and adjusting parameters, it can adapt to pipettes of different sizes such as 1mL, 5mL, 10mL, 25mL, etc., to meet the production needs of various models.

Environmental protection and energy saving: using environmentally friendly screen printing ink and UV drying method, no high temperature baking is required, energy saving and no harmful emissions.

Intelligent management, easy maintenance: automatic fault alarm, ink monitoring, production statistics and other functions are all available, convenient maintenance and data traceability.

In the production process of pipettes, two-color screen printing technology not only improves the functional performance and appearance aesthetics of the product, but also helps enterprises achieve standardized, efficient and high-quality manufacturing goals. As the core equipment of this key process, the two-color screen printer for pipettes is becoming an indispensable and important equipment in the experimental consumables industry with its high precision, high production capacity and strong adaptability. With the continuous upgrading of technology and the increasing diversification of market demand, two-color screen printing equipment will continue to drive the industry towards a higher-end and intelligent direction.