Release Date:2025-07-09 11:48:29 Popularity:

As an important experimental consumable, centrifuge tubes undertake key tasks such as sample storage, mixing, and separation. Centrifuge tubes are usually equipped with a screw cap design to ensure that there is no leakage, contamination, or loosening during high-speed centrifugation or sealed storage. With the continuous growth of demand for centrifuge tubes, the centrifuge tube automatic capping machine, as an important part of the automated packaging process, has become an ideal choice for improving production line efficiency and product quality with its advantages of high efficiency, high consistency, and intelligent control.

1. The criticality of centrifuge tube capping technology

The closure of the centrifuge tube is crucial to its use effect, and the quality of the capping is directly related to the following aspects:

Air tightness and liquid tightness: prevent sample volatilization or leakage;

Compressive strength: the cap does not loosen or break during high-speed centrifugation;

Reasonable opening torque: convenient for users to use, avoid being too tight or too loose;

Consistency and aesthetics: improve product qualification rate and market recognition.

In mass production, manual capping is difficult to ensure that each product meets the uniform standard, while automatic capping equipment achieves standardized and high-speed operation through mechanical means, greatly improving production efficiency and quality consistency.

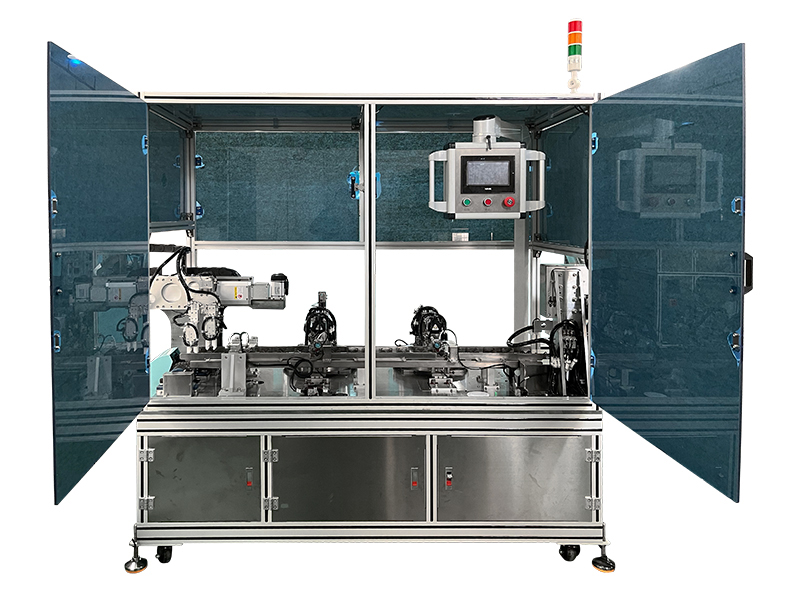

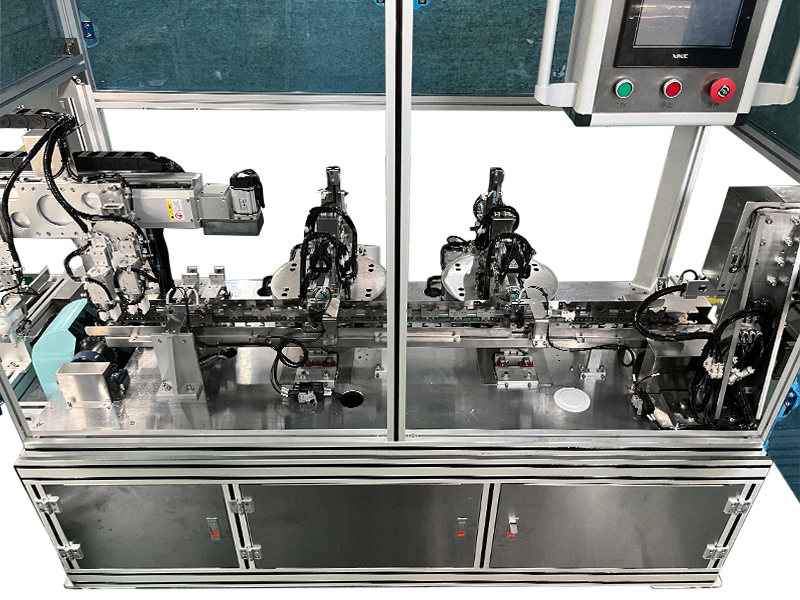

2. Working principle and structural composition of centrifuge tube automatic capping machine

The centrifuge tube automatic capping machine is a special equipment for automatic capping and tightening of centrifuge tubes of different specifications (such as 1.5mL, 15mL, 50mL, etc.). It adopts mechanical automation control and has high-precision torque adjustment and high-speed operation capabilities. Its typical structure includes:

Automatic feeding system: The centrifuge tube body and the lid are automatically separated, positioned, and transported to the capping station through a vibration plate, track or feeding belt.

Positioning and clamping system: The centrifuge tube is fixed with a pneumatic clamp or a servo clamp to prevent sliding or tipping during the capping process.

Capping mechanism: The core component is driven by a servo motor to drive the rotating shaft, accurately control the capping speed and torque, and ensure that each centrifuge tube meets the uniform tightening standard.

Torque control system: Set the torque range of capping according to product material and usage requirements to avoid the cap from cracking or being too loose.

Detection and rejection module: The visual system or torque detection module can be configured to automatically identify and reject products with poor capping, missing caps, and crooked caps.

Intelligent control system (HMI): Through PLC and touch screen interface, parameter adjustment, fault alarm, data statistics and other functions are realized, which is convenient for operation and maintenance.

3. Equipment advantage analysis

High-efficiency production: The single machine speed can reach 60 to 120 pieces per minute, which greatly improves the efficiency of the production line and meets the needs of large-volume orders.

High consistency and reliability: The tightening degree of all caps is consistent, which effectively reduces manual errors and improves the final product qualification rate.

Adapt to a variety of specifications: The fixture and program can be quickly switched, compatible with a variety of centrifuge tube models, and adapt to flexible production modes.

Non-destructive operation, avoid scratches and indentations: Use soft capping heads or anti-slip sleeves to protect the appearance of the tube body and the cap, and improve the product grade.

Can be linked to automatic assembly line: combined with automatic feeding, testing, packaging and other equipment to create a complete intelligent production line.

Save labor costs: replace manual capping, reduce labor intensity and number of workers, and reduce enterprise operating costs.

At a time when automated manufacturing has become a mainstream trend, the centrifuge tube automatic capping machine, as an important equipment in the intelligent packaging link, not only optimizes the traditional capping process, improves efficiency and consistency, but also helps enterprises move towards a new stage of intelligent manufacturing with higher standards and higher automation levels. For medical consumables manufacturers who pursue quality and efficiency, investing in automatic capping equipment is not only an improvement in productivity, but also a reflection of the brand's core competitiveness.