Release Date:2023-02-08 10:44:58 Popularity:

Non-standard automation equipment is a term that is often heard in the production industry, but there are still many people who do not understand the true meaning of the word, and many people think it is just an automated equipment. Is it just that? Literally, non-standard automation equipment is a custom product.

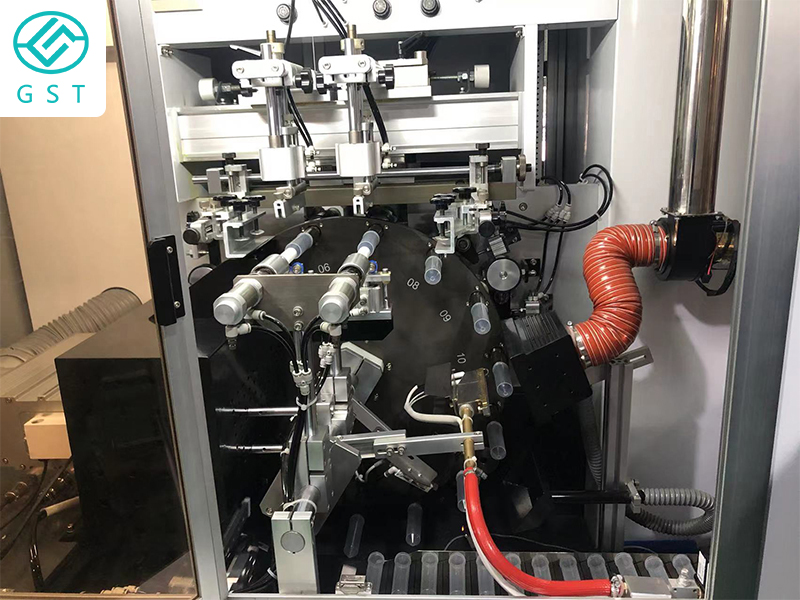

It is the only type of machinery that is customized by the user, and it is not available in the market. As we all know, standardized products can be produced in large quantities. However, for non-standard automation equipment, even if you have one now, you still need it When you are going to buy a second piece of the same equipment, you also need to order it, because this kind of product is only ordered but not sold, and it has a strong uniqueness. So, what are the characteristics of non-standard automation equipment?

1. Non-standard automation equipment solves manual production problems. For non-standard automation equipment, it was born to improve factory production efficiency, reduce costs, improve product quality or output, and to replace manual production, which is difficult to achieve station operations or actions. The reliability and stability of its equipment The performance requirements are quite strict, requiring design engineers to have a very good understanding of the product process, and analyze in detail which technical indicators the equipment should meet in order to meet the low failure rate and meet the production speed and cycle required by customers.

2. The design ability of the design engineer. Engineers who design non-standard automation equipment must have very rich design experience, be familiar with many different process requirements and indicators, be able to have a strong ability to judge the production requirements of various processes, and be able to judge various processes in a timely manner. The key points to pay attention to in production to ensure the reliability, safety and stability of equipment production. Compared with standard mechanical products, non-standard automation equipment production companies need to produce equipment according to customer needs, not standardized production in the general sense, it has higher technical requirements (at the same time it can be used in every industry application), which requires non-standard automation companies to have a considerable design team and capabilities.

3. More emphasis on standardization and modularization. Generally, it is designed and produced in strict accordance with national standards during production to ensure the purchase cost of equipment components, reliable product safety, and quality requirements. Although each user can customize products according to their own different needs, non-standard automation equipment can still use modular components (such as motors, conveyor belts, cylinders, etc., to better exert modular performance and fully reflect non-standard automation equipment. The flexibility and superiority of automation equipment.

4. High-quality equipment and components. The quality requirements of the components used in the equipment are very high, so as to ensure that the final equipment will not affect the overall performance due to component problems. The quality of the pneumatic components, guide components, circuit components, control systems, mechanical components, etc. used on the equipment is very important. It needs to be tempered through continuous testing.

5. Non-standard automation equipment pays more attention to simple design. It does not need to use very complicated equipment, and the function is customized operation, it is a relatively simple and direct and effective equipment. Some products are more popular because they have many functions, but sometimes they don’t need so many functions. What should I do? It is to use non-standard automation equipment to remove complicated parts and make the operation easier. This is also a major advantage of non-standard customization.

6. Equipment commissioning and trial production services. After commissioning to make the performance of various indicators of the equipment reach a good state, we will provide operational training to customers and training on the internal performance of the equipment and various required indicators. This is an essential step. You know how to operate a mobile phone, but for non-standard devices, you may not be able to figure out its operating habits in a short while.

The purpose of designing non-standard automation equipment is to improve the production efficiency and production capacity of the enterprise, thereby reducing the wages of workers and the cost of unnecessary losses caused by manual operations. It can be targeted, precise, simple, and targeted. But for non-standard automation equipment production companies, there are undoubtedly higher requirements, whether it is design, procurement, production, commissioning, post-use training and other links.