Release Date:2023-07-20 09:45:05 Popularity:

Screen printing machine is an efficient printing equipment that can print images and text on various materials. Its working principle is very complicated and involves multiple links and steps. This article will introduce the working principle of the screen printing machine in detail to help readers understand this technology in depth.

First of all, the workflow of the screen printing machine includes four stages: design, plate making, printing and post-processing. The design stage is mainly to design patterns and characters according to the requirements of customers, and the plate-making stage is to convert the designed patterns and characters into actual printing plates. In the printing stage, the screen printing machine directly prints patterns and characters on the substrate, and in the post-processing stage, it performs necessary processing on the printed matter, such as drying and curing.

The working principle of the screen printing machine can be subdivided into the following steps:

Positioning and fixing of the substrate: The screen printing machine first needs to fix the substrate on the printing table to ensure that the printing position is accurate.

Coating sensitizer: In the plate making stage, it is necessary to apply a sensitizer to make the printing plate have photosensitivity.

Exposure: transfer the designed pattern or text to the printing plate by exposure.

Development: The pattern or text after exposure is revealed through the developer solution.

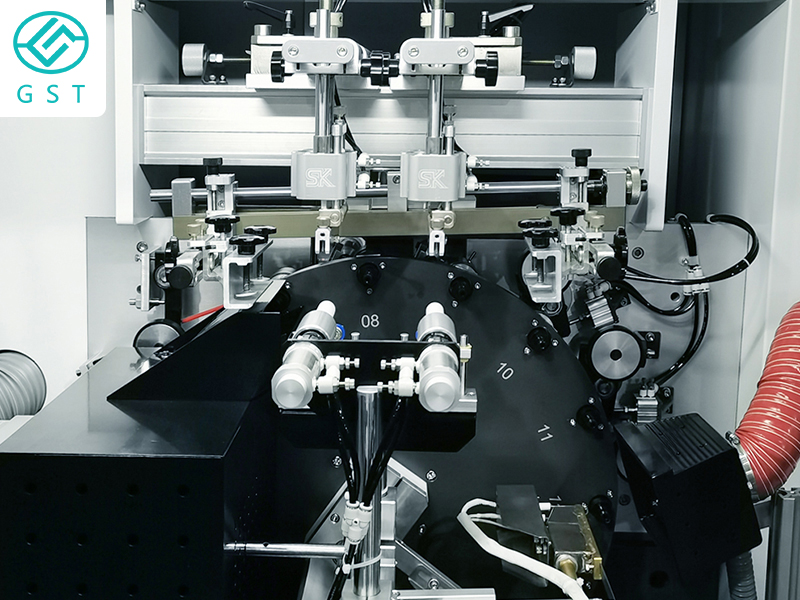

Screen printing: Fix the developed printing plate on the screen printing machine, and print the ink onto the substrate through the screen by applying pressure.

Drying and curing: After printing, the printed matter needs to be dried and cured to fix the ink on the substrate.

The working principle of the screen printing machine involves multiple technologies and steps, and a mistake in any link may affect the final printing effect. Therefore, when operating the screen printing machine, it is necessary to strictly abide by the operating procedures to ensure that every link meets the requirements.

Generally speaking, the working principle of the screen printing machine is a highly complex printing technology, which requires the precise cooperation of multiple links and steps. Through an in-depth understanding of the working principle of screen printing machines, we can better master this technology and achieve higher quality printed matter production.

Finally, it should be noted that the technology of screen printing machines is constantly developing, and its working principles and equipment are also constantly being upgraded and improved. Therefore, the introduction in this article is only a basic description of the working principle of the screen printing machine, and the specific operation and technical application may vary due to different equipment models and usage occasions. In the specific operation, it is necessary to refer to the equipment manual and related technical information to ensure the printing quality and efficiency.

In short, the working principle of the screen printing machine is a topic worthy of in-depth discussion, which requires us to continue to learn and explore. Only by fully understanding and mastering this technology can we better respond to various printing needs and achieve higher quality printed matter production.