Release Date:2023-12-15 10:37:00 Popularity:

With the rapid development of science and technology, production automation assembly lines have become an important pillar of modern manufacturing. They not only improve production efficiency and reduce production costs, but also bring huge commercial value to enterprises. This article will take an in-depth look at the benefits and applications of automated production lines, and how it will change the future of production.

1. Advantages of automated production lines

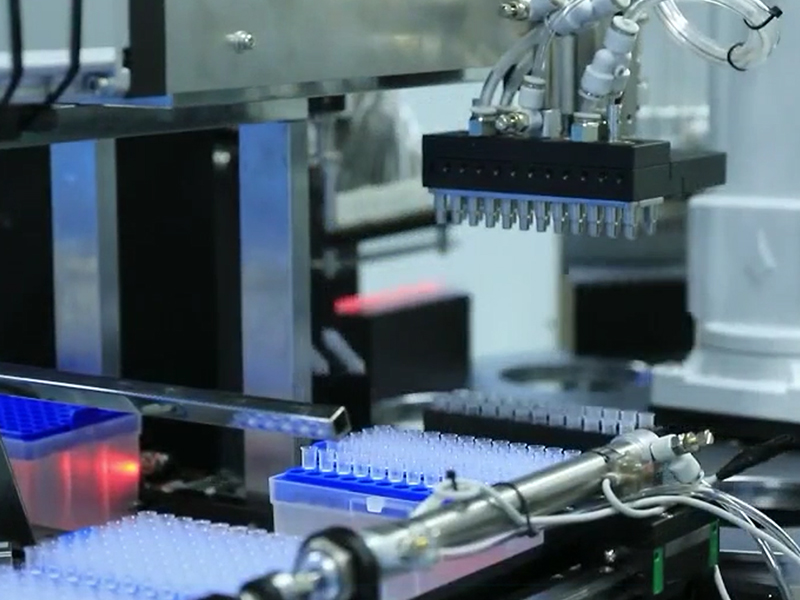

The production automation assembly line is a highly automated production line that can process, assemble and package raw materials, semi-finished products and finished products in a certain order and process. In this process, automated equipment replaces traditional manual operations, greatly improving production efficiency and quality.

Improve production efficiency: The automated production line can produce continuously, avoiding downtime and waste caused by human factors. At the same time, because the equipment can operate 24 hours a day, production efficiency has been greatly improved.

Reduce production costs: The use of automated production lines can reduce labor costs because a large number of workers are no longer required to operate. At the same time, because the production process is more precise and efficient, the waste of raw materials and energy consumption can be reduced.

Improve product quality: Automation equipment has higher precision and stability, which can reduce human operating errors and improve product quality and stability.

2. Application fields of production automation assembly lines

Production automation assembly lines are widely used in various industries. Below we will introduce several typical examples.

Automobile manufacturing industry: The automobile manufacturing process requires a large number of assembly line operations. Automated equipment can efficiently complete complex processes such as body welding, painting, and assembly, greatly improving production efficiency and quality.

Electronic manufacturing industry: Electronic manufacturing industry requires a lot of manual operations, such as patching, assembly, testing, etc. The use of automated production lines can complete these processes quickly and accurately, while also improving product quality and stability.

Food processing industry: The food processing industry requires a large amount of machinery and equipment for processing, packaging and warehousing. Production automation assembly lines can efficiently complete these tasks and improve production efficiency and quality.

3. Development Trend of Production Automation Lines

With the continuous development of science and technology, production automation assembly lines are constantly being upgraded and improved. In the future, we will see more intelligent, flexible and sustainable automated production lines.

Intelligent: The future production automation assembly line will be more intelligent, with the ability to adapt, self-learn and make decisions. They can automatically adjust production parameters and processes according to production needs and environmental changes, improving production efficiency and product quality.

Flexibility: The future production automation assembly line will be more flexible and can adapt to the production needs of multiple varieties and small batches. They can quickly switch production and processes through modular and reconfigurable designs, improving the company's market response speed and competitiveness.

Sustainability: Future automated production lines will pay more attention to environmental protection and sustainable development. They will use more efficient energy utilization technologies and environmentally friendly materials to reduce environmental impact and resource waste.

The production automation assembly line is one of the core and key technologies of modern manufacturing. It is constantly being upgraded and improved to adapt to the growing production needs and social changes. With the continuous development of intelligent, flexible and sustainable technologies, production automation assembly lines will play a more important role in future production and create a better life and future for mankind.